| Diesel Engine | 115 kW |

| Max. Hoist | 70 kN |

| Weight | 5.8 t |

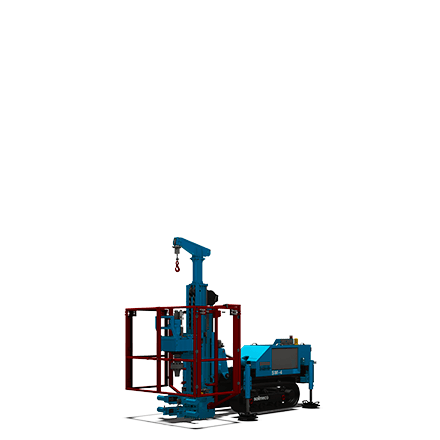

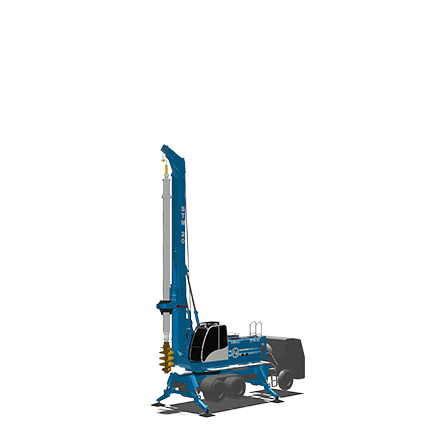

SM- 4

SM-4 is a new drilling machine featuring a separate power pack and the same movements of its larger sister, the SM-5. It has two different engine sizes available: 115 kW and 110 kW respectively (diesel and electrical).

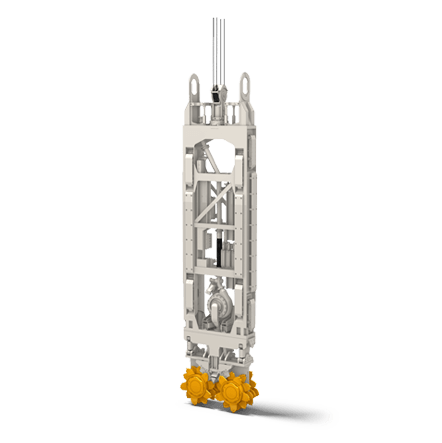

Among the many options the most interesting one is certainly the LHR kit (Low Head Room) suitable for 600 mm diameters auger drilling, with cased pilot hole.

Reviews

There are no reviews yet.