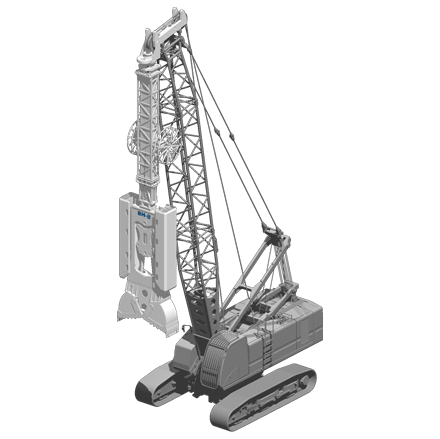

The<strong> SF-50 </strong>drilling rig, is the evolution of the already existing equipment dedicated to Continuous Flight Auger drilling technique.

The upper structure of the <strong>SF-50 </strong>is mounted on Soilmec base carrier and has been designed to perform:

- <a href="http://www.soilmec.com/en/products/cfa_piling_rigs/viewdoc.asp?co_id=3600">CFA</a> (Continuous Flight Auger) piles by means of long auger string.

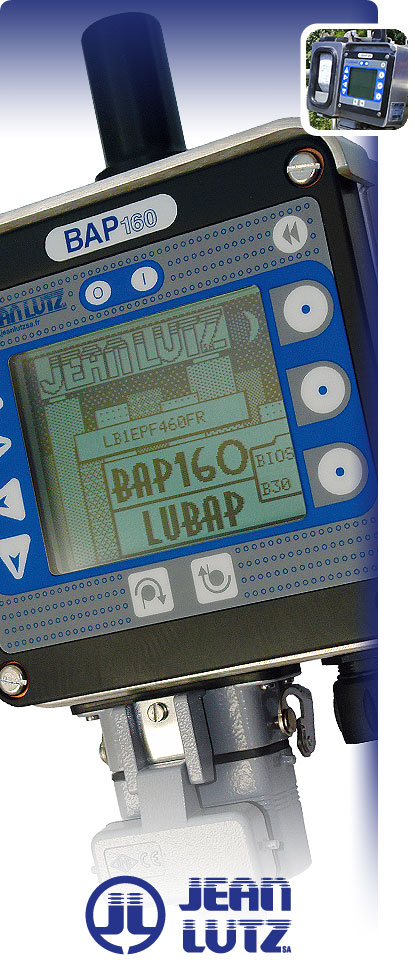

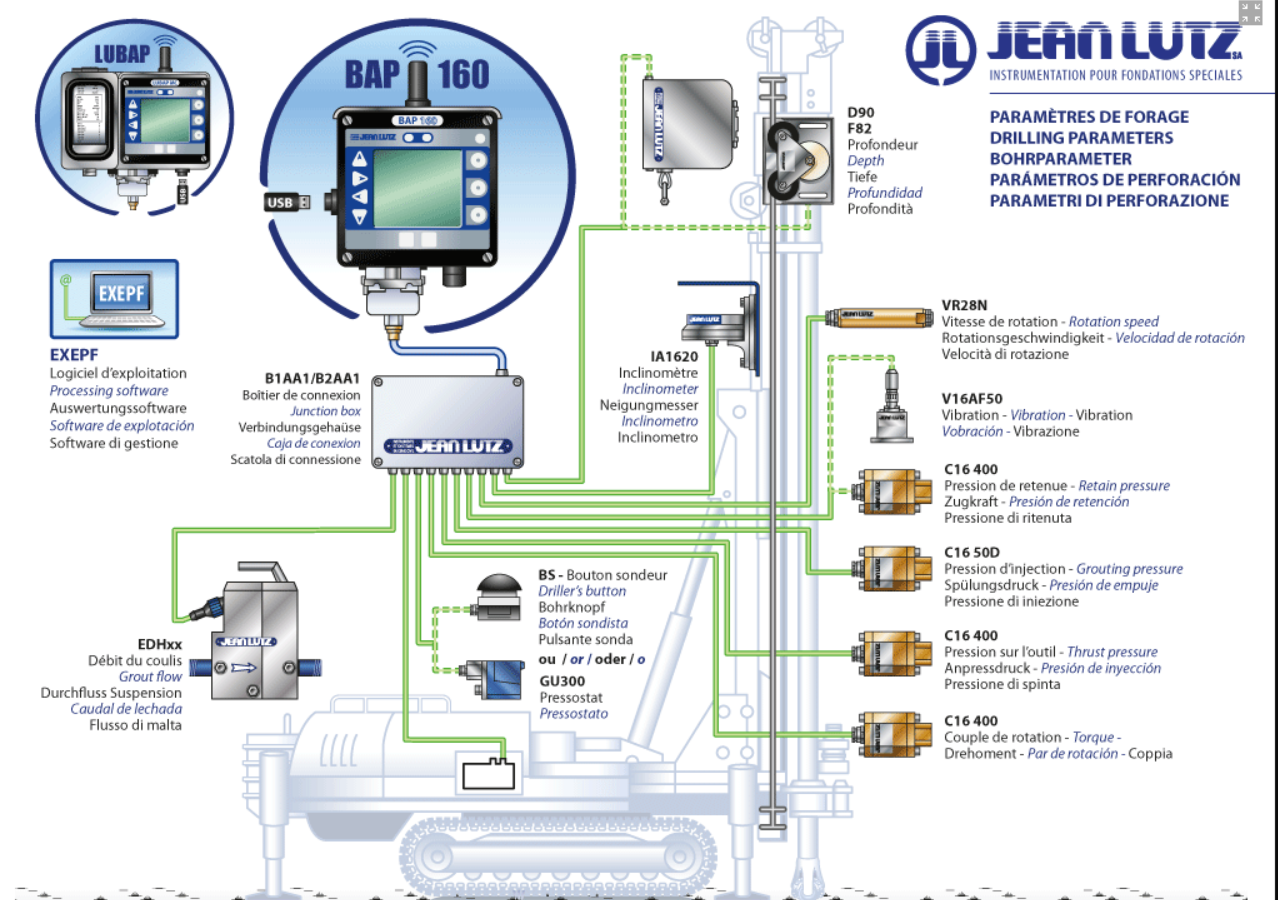

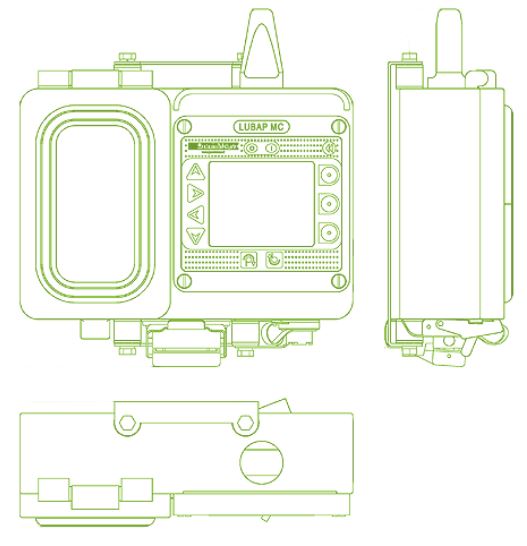

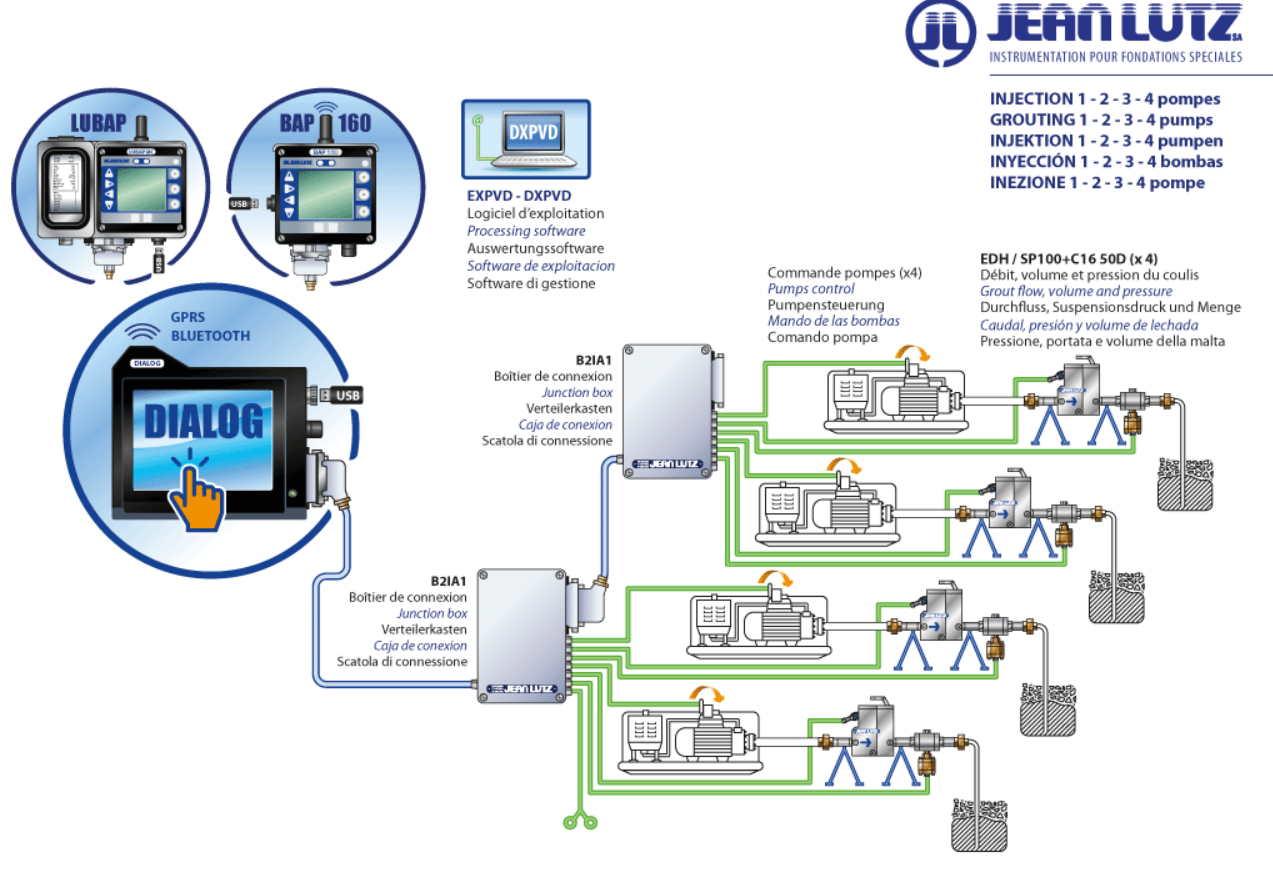

The <strong>SF-50</strong> is equipped with the DRILLING MATE SYSTEM (DMS) on 12' touch screen for monitoring and control of the rig performances and operating parameters.

Read more

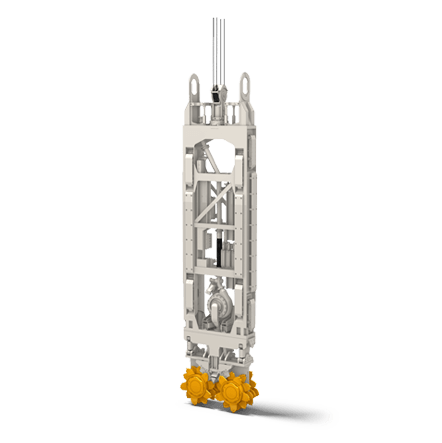

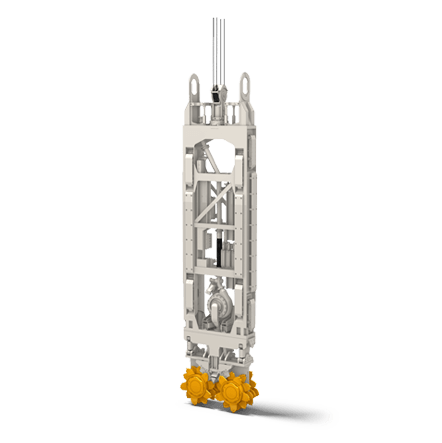

The hydromill module is constituted by a heavy steel frame on which two milling drums and a centrifugal mud pump are mounted. In order to correct the module verticality deviation, 12 independent mobile flaps are positioned on the module surface. Furthermore, a simultaneous or independent tilting plate can be installed as optional for the best verticality correction, especially in case of leaned layers of rock. All Soilmec modules are set with a 2D or 3D sensor developed for the module positioning control, which is managed by the Hydromill DMS.

Soilmec has designed all its modules with a rotation system conceived for T-panel execution or for other module orientations. This specific feature gives the possibility to facilitate the job site operations, leading to a reduction in terms of cost and time.

The 30 t class module is especially designed for Cougar version and urban job sites. It can be fitted with a cutting unit up to 102 kNm torque in order to cover the major requests in terms of panel dimensions and soil stratigraphy. The module rotation system is included as a standard.

Read more

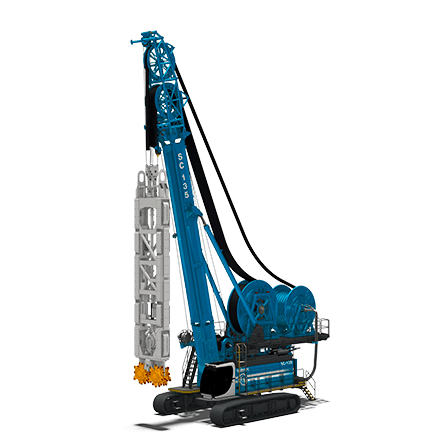

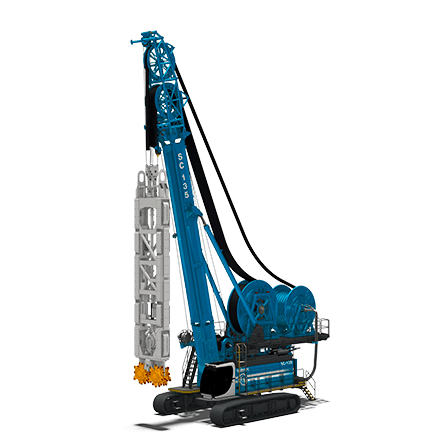

With the aim of meeting the need for increased diaphragm wall depth in the most challenging soil conditions, Soilmec has designed the “HDD” (Hose Drums Design) hydromill configuration. Hydraulic and mud winders are positioned on a base carrier, allowing high depth drilling performances.The new SC-135 Tiger is designed for a perfect job site suitability, allowing to work in a wide range of working radius and module rotations. The equipment features several improvements, especially in terms of safety and oil contamination, which are the result of years of drilling experience.This equipment gathers together all the best ideas put forward by job site experts who use the hydromill daily:

<ul>

<li>A specially-designed hydraulic system aimed at avoiding any possible breakdown due to bentonite contamination</li>

<li>Easy and safe assembly</li>

<li>Best access solutions for maintenance</li>

<li>Highest productions performed by the new Tier4f 950 HP diesel engine</li>

<li>Hose drums and cathead layout optimized to work in several working radius and module orientations</li>

</ul>

The SC-135, complying with CE requests of EN16228, has been conceived to offer the best possible safety solutions. The equipment presents a new safe anti-falling system, handrails and ladders, lashing points, remote control boards and reduced speed mode in order to carry out the main assembly/disassembly operations and maintenance procedures in safe conditions. Furthermore, this equipment has been designed for a modular assembly, with a max transportation weight of 45 t (106,000 lb).

Read more

The Soilmec hydraulic grabs are the result of years of research and development in mechanical excavation. The collection of data from various sites, tests on different soil types, the study of the performance of difficult soft soils and layers allowed the production of the series of hydraulic grabs more competitive available on the market.

They can operate in any soil type coarse or cohesive. In the presence of large boulders or hard conglomerate formations, we recommend the traditional chiseling.

Read more

Reviews

There are no reviews yet.