Soilmec rigs are self-mounting, easily transportable and designed to giving the best drilling solutions.

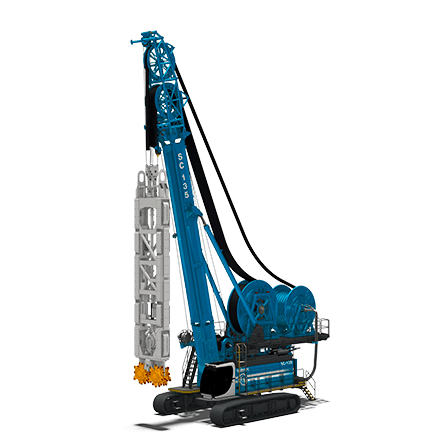

The hydraulic drilling rig <strong>SR-75 </strong>has been specially designed for suiting the following applications:

- <strong>LDP</strong> cased bore piles with casing driven directly by rotary head or optionally by casing oscillator powered by the base carrier itself;

- <strong>LDP</strong> deep uncased bored piles stabilized by drilling fluid or dry hole;

- <strong>LHR</strong> (Low Head Room) – large diameter bored piles;

- <strong>CFA</strong> (Continuous Flight Auger) piles by means of long auger string;

- <strong>CAP</strong> (Cased Augered Piles) piles with double independent rotary system;

- <strong>DP</strong> (Displacement Piles) / <strong>TCT</strong> (traction compacting tool);

- <strong>TJ</strong> (Turbojet®) / <strong>TTJ</strong> (Twin Shaft Turbojet) - soil consolidation;

- <strong>RCDS</strong> (Reverse Circulation Drilling System) on demand.

The <strong>SR-75</strong> is equipped with the DRILLING MATE SYSTEM (DMS) on 12' touch screen for monitoring and control of the rig performances and operating parameters.

Read more

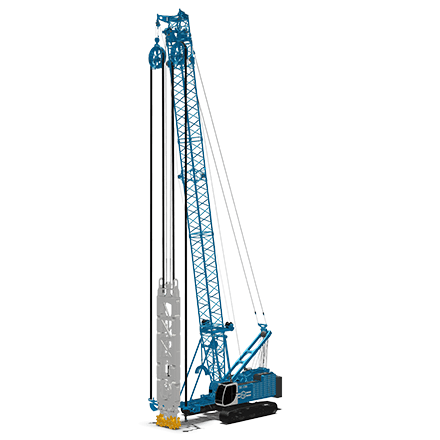

With the aim of meeting the need for increased diaphragm wall depth in the most challenging soil conditions, Soilmec has designed the “HDD” (Hose Drums Design) hydromill configuration. Hydraulic and mud winders are positioned on a base carrier, allowing high depth drilling performances.The new SC-135 Tiger is designed for a perfect job site suitability, allowing to work in a wide range of working radius and module rotations. The equipment features several improvements, especially in terms of safety and oil contamination, which are the result of years of drilling experience.This equipment gathers together all the best ideas put forward by job site experts who use the hydromill daily:

<ul>

<li>A specially-designed hydraulic system aimed at avoiding any possible breakdown due to bentonite contamination</li>

<li>Easy and safe assembly</li>

<li>Best access solutions for maintenance</li>

<li>Highest productions performed by the new Tier4f 950 HP diesel engine</li>

<li>Hose drums and cathead layout optimized to work in several working radius and module orientations</li>

</ul>

The SC-135, complying with CE requests of EN16228, has been conceived to offer the best possible safety solutions. The equipment presents a new safe anti-falling system, handrails and ladders, lashing points, remote control boards and reduced speed mode in order to carry out the main assembly/disassembly operations and maintenance procedures in safe conditions. Furthermore, this equipment has been designed for a modular assembly, with a max transportation weight of 45 t (106,000 lb).

Read more

The hydromill module is constituted by a heavy steel frame on which two milling drums and a centrifugal mud pump are mounted. In order to correct the module verticality deviation, 12 independent mobile flaps are positioned on the module surface.

Furthermore, a simultaneous or independent tilting plate can be installed as optional for the best verticality correction, especially in case of leaned layers of rock. All Soilmec modules are set with a 2D or 3D sensor developed for the module positioning control, which is managed by the Hydromill DMS.

Soilmec has designed all its modules with a rotation system conceived for T-panel execution or for other module orientations. This specific feature gives the possibility to facilitate the job site operations, leading to a reduction in terms of cost and time.

The 40 t class module is suggested for medium-high depth projects. Its body length and weight guarantee a high verticality level and panel dimensions up to 3200x1800 mm. The high torque cutting unit (up to 153 kNm) can be installed.

The module rotation system is included as a standard

Read more

The demand for diaphragm wall equipment suitable to urban areas and the stringent requirement of verticality make the hydromill Cougar a good and easy option to meet the customer’s needs.

The Hose Wheels Design (HWD) is positioned below the cathead so that it can easily follow the hydromill movements with a tensioning and rewinding automatic system. It arises from the need to move simultaneously the hydraulic and bentonite mud circulation hoses to the cutting unit.

The SC-120 Cougar is the high performance HWD series, which excavates more than 60 m of depth with approx. 900 HP ensuring a great level of production rates.

The SC-120, complying with CE requests of EN16228 upon request, has been conceived to offer the best possible safety solutions. The equipment presents a new safe anti-falling system, handrails and ladders, lashing points, remote control boards and reduced speed mode in order to carry out the main assembly/disassembly operations and maintenance procedures in safe conditions.

The DMS (Drilling Mate System), developed by Soilmec and installed on all the products of the range, allows the real-time monitoring of all the operating parameters and of the production process, including a dual-axis positioning sensor (triple-axis version as optional) that controls the geometry of the panel with 2D and 3D graphics print out.

Read more

Reviews

There are no reviews yet.