<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-1" class="descr">

<div class="first column">

Drillmec manufactures derricks and masts for all applications, and, in addition, packages can be furnished with top drives, motion compensators, racking system, pipe handlers, elevators, top mounted flares and all derrick related equipment for complete packages. Drillmec offers a complete range of masts that can be telescopic, bootstrap, cantilever, and barge mounted units. In the design phase, particular care is given to weight, space, environmental loading conditions and operational capacities.

</div>

<div class="last column">

<p class="split">These are the main features of Drillmec derricks:</p>

<ul>

<li>Welded or bolted derricks</li>

<li>Suitable for triple and quadruple stands accommodation</li>

<li>Racking board equipped with racker and stand maker systems</li>

</ul>

</div>

</div>

</div>

</div>

Read more

<div class="first column">

<ul>

<li>Drillmec’s deep roots in the manufacturing of drilling rigs start back in 1929 and since then continuously improved rig design by raising the pull-up capacity, enhancing safety, optimizing performance and minimizing environmental impact.

Drillmec starting from Massarenti & Branham-design produces a full range of land rig packages to satisfy almost any need with successful achievements all over the world.

Drillmec understands that drilling contractors objectives and conditions are constantly</li>

<li>in flux and require different solutions to achieve results. Drillmec rigs are available in a wide range of specifications in order to fit custom configurations and capabilities</li>

</ul>

</div>

<ul>

<li><strong>Land Rigs - Swing Lift Series</strong>

Drillmec produces swing lift rigs with raising lines or hydraulic cylinders. The Swing Lift Series is designed for fast and safe rig-up and rig-down, minimizing non-productive time.</li>

<li><strong>DM SERIES </strong>( Swing Lift Series, Raising Lines)<strong>

</strong> Swing Lift masts and substructures with hook load capacity from 340 to 907 metric tons (750,000 - 2,000,000 lbs).<strong>HSL SERIES </strong>(Hydraulic Swing Lift Series, Hydraulic Raising)<strong>

</strong>Hydraulic Swing Lift masts and substructures with hook load capacity from 340 to 680 metric tons (750,000 - 1,500,000 lbs).</li>

</ul>

Read more

<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-1" class="descr">

<div class="first column">

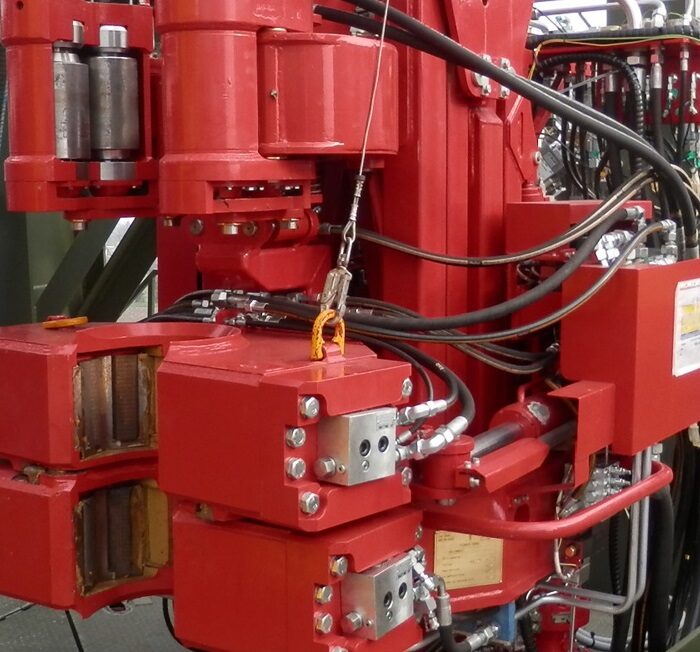

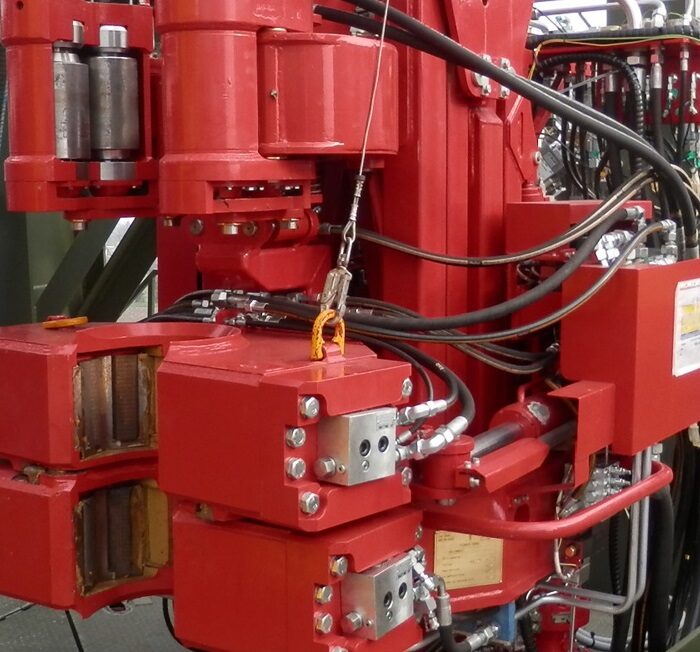

<strong>DRILLMEC's Compact Power Tong</strong> is able to offer high torque performances with very quick operations.

Drillmec PCT system, consist mainly of:

</div>

<div class="last column">

<ul class="split">

<li class="split">Set of hydraulic cylinders for vertical and horizontal power tong moving</li>

<li>Spinning system</li>

<li>Pedestral/Positioning</li>

<li>Rotating clamps</li>

</ul>

</div>

<strong>PCT Series Main features</strong>

</div>

</div>

</div>

<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-2" class="descr">

<div class="first column">

<ul>

<li>Can be installed directly on rig floor through a pedestal, can be powered by a Hydraulic Power Unit (stand alone system) or by the auxiliary rig’s HPU.</li>

<li>Controls are located in the driller cabin and on the drill floor, connected to the PCT by cables, allowing remote operation handling at safe distance<strong> </strong></li>

</ul>

</div>

<div class="last column">

<p class="split"><strong class="split">PCT Series Main Benefits:</strong></p>

<ul>

<li>Controls positioned on the handling arm frame available in case of emergency</li>

<li>Easy installation and handling procedure, two pad eyes rated 17 ton each top mounted for lifting operations</li>

<li>Equipped with one limit switch that stops upper clamp rotation during make-up phase</li>

<li>High torque performance and wide OD range availability</li>

</ul>

</div>

</div>

</div>

</div>

Read more

1- Heavy-duty horizontal centrifugal dredging pumps manufactured from wear-resistant ni-hard and manganese steel.

– Extremely efficient

– Wear resistant

– Long working life

– Easy disassembly

– Limited maintenance

– Ready availability of spare parts

– Single and double-walled versions

Read more

Reviews

There are no reviews yet.