Soilmec rigs are self-mounting, easily transportable and designed to giving the best drilling solutions.

The hydraulic drilling rig <strong>SR-45 </strong>has been specially designed for suiting the following applications:

-<strong> LDP</strong> cased bore piles with casing driven directly by rotary head or optionally by casing oscillator powered by the base carrier itself;

-<strong> LDP</strong> deep uncased bored piles stabilized by drilling fluid or dry hole;

-<strong> LHR </strong>(Low Head Room) – large diameter bored piles;

-<strong> CFA</strong> (Continuous Flight Auger) piles by means of long auger string;

-<strong> DP</strong> (Displacement Piles) / <strong>TCT</strong> (traction compacting tool);

-<strong> TJ</strong> (Turbojet®) /<strong> TTJ </strong>(Twin Shaft Turbojet) - soil consolidation.

The <strong>SR-45</strong> is equipped with the DRILLING MATE SYSTEM (DMS) on 12' touch screen for monitoring and control of the rig performances and operating parameters.

Read more

The <strong>SF-65 </strong>drilling rig, is the evolution of the already existing equipment dedicated to Continuous Flight Auger drilling technique.

The upper structure of the <strong>SF-65 </strong>is mounted on Soilmec base carrier and has been designed to perform:

- <a href="http://www.soilmec.com/en/products/cfa_piling_rigs/viewdoc.asp?co_id=3600"><strong>CFA </strong></a>(Continuous Flight Auger) piles by means of long auger string.

The <strong>SF-65 </strong>is equipped with the DRILLING MATE SYSTEM (DMS) on 12' touch screen for monitoring and control of the rig performances and operating parameters.

Read more

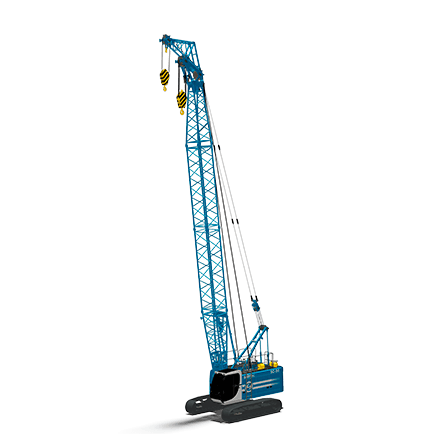

<strong>SC-50 HD</strong> is a Soilmec crane with an <strong>hydraulic proportional control </strong>system that provides accurate and simultaneous movements. Regarding performance, the maximum capacity is 50 tons with a working radius of about 3.6 m; the diesel engine power (201 kW) and the hoisting force (150 kN) are greater than those of the main competitors’ cranes.

Another advantage is the <strong>new Soilmec cab</strong>, very comfortable for the operator and, especially, its innovative control panel.

Finally, we have to highlight the different possible operating configurations (crane, hydraulic grab, cable grab, hydraulic rotary, dragline, etc.), which allow the SC-50 HD to be suitable for a large range of building yards.

Read more

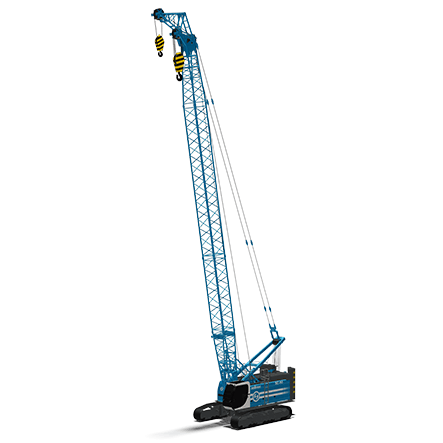

<strong>SC-90 HD</strong> is a Soilmec crane with an <strong>electro-hydraulic proportional control </strong>system that provides accurate and simultaneous movements. Regarding performance, the maximum capacity is 90 tons with a working radius of about 3.6 m; the diesel engine power (470 kW) and the hoisting force (297 kN) are greater than those of the main competitors’ cranes.

Another advantage is the <strong>new Soilmec cab</strong>, very comfortable for the operator and, especially, its innovative control panel.

Finally, we have to highlight the different possible operating configurations (crane, hydraulic grab, cable grab, hydraulic rotary, dragline, etc.), which allow the SC-90 HD to be suitable for a large range of building yards.

Read more

Reviews

There are no reviews yet.