The<strong> SF-50 </strong>drilling rig, is the evolution of the already existing equipment dedicated to Continuous Flight Auger drilling technique.

The upper structure of the <strong>SF-50 </strong>is mounted on Soilmec base carrier and has been designed to perform:

- <a href="http://www.soilmec.com/en/products/cfa_piling_rigs/viewdoc.asp?co_id=3600">CFA</a> (Continuous Flight Auger) piles by means of long auger string.

The <strong>SF-50</strong> is equipped with the DRILLING MATE SYSTEM (DMS) on 12' touch screen for monitoring and control of the rig performances and operating parameters.

Read more

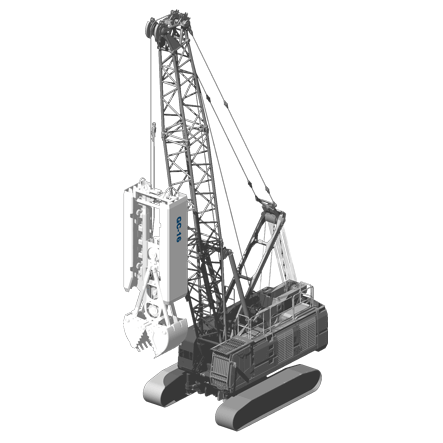

GC serial mechanical grabs are rope suspended and rope operated. Side guides and jaws are interchangeable in order to perform different panel sizes with the same grab body.

Read more

STM-30 is a drill unit designed to be fast, highly productive and easy to operate. It's a fully hydraulic drilling rig mounted on standard, heavy duty 6 x 4 truck. Thanks to its power, reliability and new configuration, the STM-30 meets with the needs for a high performance and easy to mobilize drilling rig.

The application is:

<strong>- <a href="http://www.soilmec.com/en/viewdoc.asp?co_id=3596">LDP</a></strong> deep uncased bored piles stabilized by drilling fluid or dry hole.

Read more

Soilmec rigs are self-mounting, easily transportable and designed to giving the best drilling solutions.

The hydraulic drilling rig <strong>SR-145 </strong>has been specially designed for suiting the following applications:

- <strong>LDP</strong> cased bore piles with casing driven directly by rotary head or optionally by casing oscillator powered by the base carrier itself;

- <strong>LDP</strong> deep uncased bored piles stabilized by drilling fluid or dry hole;

- <strong>CFA</strong> (Continuous Flight Auger) piles by means of long auger string;

- <strong>CAP</strong> (Cased Augered Piles) piles with double independent rotary system;

- <strong>DP</strong> (Displacement Piles) /<strong> TCT </strong>(traction compacting tool);

- <strong>TJ</strong> (Turbojet®) / <strong>TTJ</strong> (Twin Shaft Turbojet) - soil consolidation;

The <strong>SR-145 </strong>is equipped with the DRILLING MATE SYSTEM (DMS) on 12' touch screen for monitoring and control of the rig performances and operating parameters.

Read more

Reviews

There are no reviews yet.