GTE Transverse Thrusters

A Wide Range of Reliable , Heavy – Duty Thrusters Designed to Guarantee Continuous Operation in All Conditions.

Categories: Italdraghe, Oil & Water, Transverse Thrusters

Related products

-

SGT 180 cutter suction dredgers

1- Key features of Italdraghe dredgers :- – Up-to-date yet easy to operate – Easy to maintain – Centrally controlled by just one operator – Use of well-known branded components – Spacious, sound-proofed control cabin with 360° vision – Powerful, reliable pumps able to discharge over great distances – Spacious engine room with all round access to equipment – Cutter heads with replaceable teeth – Customised to specific client requirements – Dismountable for easy transportRead more -

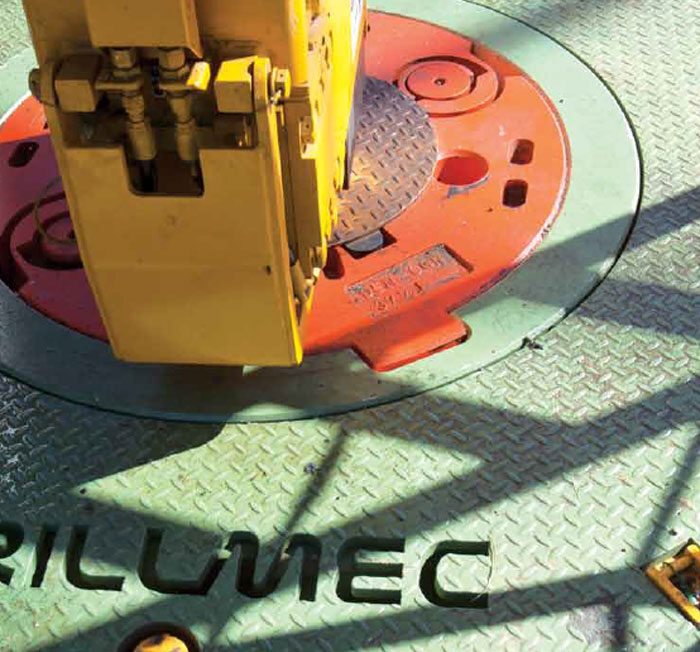

Rotary table

<div class="first column"> Drillmec rotary table is designed for rough conditions and complies with the strictest approvals for the drilling industry. Drillmec’s rotary table “R Type” are designed, in accordance with the industry standards, for drilling depths up to 30,000 FT and beyond. Driven by electric or hydraulic power, “R Type” are interchangeable with the most popular rotary table brands. </div> <div class="last column"> <p class="split">Drillmec’s quality department inspects all phases of manufacture and every item is tested in our premesis before delivery.</p> </div>Read more -

Derrick equipment set for tender assisted rigs

<div class="first column"> In addition to Pre-FEED, FEED and EPC of drilling packages and drilling modules, DRILLMEC offers a comprehensive line of Tender Assisted DES to be applied not only on fixed platforms and jackets, but also for deeper water operations on TLPs and SPARs. DRILLMEC DES design focuses on the following key advantages and main aspects: <ul> <li>Light weight design</li> <li>Minimized quantity of loads - downt to 3, depending on client's preferences and lifting requirements</li> <li>Quick and safe rig-up operations</li> <li>Maximized tripping speed and set-up for offline operations</li> </ul> </div> <div class="last column"> <p class="split">Drilllmec's typical activities for Tender Assisted DES and Modular Rigs include the following:</p> <ul> <li>Conceptual design, front-end engineering and detailed engineering</li> <li>Project Management</li> <li>Supply of complete drilling equipment, mud equipment and third party equipment</li> <li>Fabrication and/or construction supervision</li> <li>Installation, testing, commissioning and site assistance</li> <li>24/7 After sales assistance and support</li> </ul> </div>Read more -

SGT 600 C cutter suction dredgers

1- Key features of Italdraghe dredgers :- – Up-to-date yet easy to operate – Easy to maintain – Centrally controlled by just one operator – Use of well-known branded components – Spacious, sound-proofed control cabin with 360° vision – Powerful, reliable pumps able to discharge over great distances – Spacious engine room with all round access to equipment – Cutter heads with replaceable teeth – Customised to specific client requirements – Dismountable for easy transportRead more

Reviews

There are no reviews yet.