<div class="first column">

Since 1996, about two hundred Drillmec HH rigs have been working all around the world in many environmental and weather conditions, always delivering high safety and drilling efficiency.

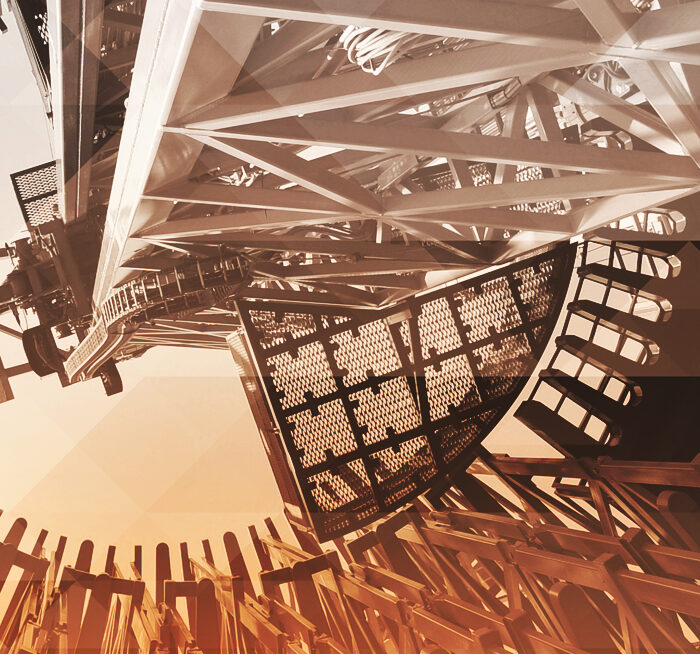

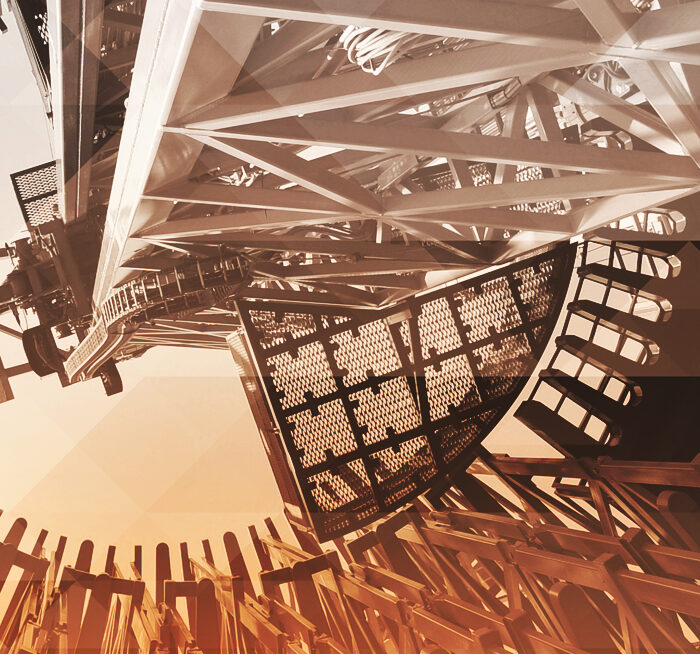

On the basis of the HH Series experience and field results, Drillmec has developed a new generation of fully automated drilling rig forward, named AHEAD (Advanced Hydraulic Electrical Automated Driller), designed to meet the highest HSE standards and drilling efficiency.

Combining the advantages of DRILLMEC Hydralic Rig Series with the capability of working with double (R3) or triple stand (R2) make this new evolution of design a complete revolution in the oil industry.

This rig, compared to a conventional land rig, has a footprint reduction up to 40%, a reduced visual impact and enginereed for a low noise level.

</div>

Read more

<div class="first column">

Drillmec product line can also offer different auxìliary Equipment, such as:

<strong>Drilling Fluid Equipment – Mud System, Bulk Storage and Transfer, Mud Tanks, Mud Guns, Mud Monitoring, Seawater Cooling Units

</strong>

DRILLMEC designs and manufacture complete mud and bulk systems to be integrated into a complete DRILLMEC drilling package to offer a full integrated solution. DRILLMEC offering and portfolio includes standardized solutions as well as tailor made ones in accordance to specific needs and project requirements.

<strong>Skidding Systems

</strong>

DRILLMEC Skidding Systems are designed and tailor made according to specific drilling rig configuration, operational requirement and overall well slots to be covered.

DRILLMEC Skidding Systems portfolio include the conventional models:Gripper Jack type

<ul>

<li>Ratchet Jack</li>

<li>Lift & Roll</li>

</ul>

Combined with some unconventional skidding solutions for special applications :

<ul>

<li>Walking Systems</li>

<li>Rotating Hydraulic Driven Pivoting Wheels</li>

</ul>

Main characteristics taken into consideration where designing a skidding systems are the following main ones: capping beams size, distance between the wells, directions to cover, capping beams maximum allowable pressure and overall skidding capacity.

<strong>HPU

</strong>

Hydraulic power unit (HPU) is a critical part of a rig and all its operations.

DRILLMEC with its experience in Hydraulic Rigs and Hydraulic Equipmnet is capable to offer a wide range of hydraulic power units suitable to meet any customer application, international standard and capable to feed from individual equipment to complete drilling packages.

<strong>Air Unit</strong>

DRILLMEC air units are designed and tailor made in accordance to package requirements and pneumatic consumers on board of the drilling package.

<strong>Hydraulic Cathead</strong>

DRILLMEC Jack type hydraulic cathead system is composed by: hydraulic cylinder with wire line consisting of cylinder with backup post, anchor Adapter,

</div>

<div class="last column">

<p class="split">and wireline assembly.</p>

<strong>Top Drive and Travelling Block Retractable Dolly</strong>

DRILLMEC Dolly and block Retract Systems are designed both Top Drives and Travelling blocks in order to increase tripping speed and optimize drilling efficiency.

The Retractlable Dolly System is a custom designed parking system, specifically engineered to be integrated with derrick structures and drill floor arrangements on offshore rigs.

</div>

Read more

<span style="font-size: 8pt;">CBM Series is a special purpose line of drilling rigs and related equipment designed to meet specific requirements of shallow and deeper wells.

</span><span style="font-size: 8pt;"><strong>HH 55 - HH 75 - HH 102</strong> </span>

<span style="font-size: 8pt;">HH 55 - HH 75 - HH 102 are drilling rigs suitable for CBM Coal Bed Methane exlporation. The mast is telescopic and operates as a hydraulic hoist. The hydraulic top drive is permanently installed in its cradle and it doesn’t need to be removed during transportation. Therefore all the rig can be easily assembled without any crane.

</span>

<span style="font-size: 8pt;">An auxiliary jib crane on the mast side facilitates the rig up and allows to pick up tubular and various equipment from the ground to the drill floor. Drillmec completes ts package with power slips, power tong, torque wrench, casing make up device and bit break out tong. In the easiest configuration a pneumatic over hydraulic panel is on the mast side whereas a cyber chair can be supplied. Customizable control cabin with air conditioning system and self elevating system is provided upon request, as well as a powered rotary table.</span>

Read more

<div class="first column">

Drillmec’s Control Cabins are specifically designed and tailor made for each individual drill floor, from land rig single sit operation up to triple sits control cabins for floaters.

Driller Cabin are equipped with air conditioning system and air pressurizing system and all components inside the cabin are designed for safe-area and ex-proof if necessary.

It is crucial for rig operators and personnel to have full access to interact with the rig during all drilling operations.

DRILLMEC offers also last generation <strong>Cyber Chairs </strong>as an Integrated Drilling Control System allowing the Driller to manage, control and monitor rig floor equipment in four

</div>

<div class="last column">

<p class="split">PC Panels to ensure safe, efficient and seamless operations.</p>

The <strong>Data Mate System (DMS) </strong>provides the rig operator with vital information to manage productivity during drilling and production operations. All the information can be display locally or transmitted to remote for supervisory service or troubleshoorting.

Drillmec’s extensive knowledge and experience with drilling and equipment helped us develop innovative tools that simplifies the operator’s job.

</div>

Read more

<div class="first column">

In addition to Pre-FEED, FEED and EPC of drilling packages and drilling modules, DRILLMEC offers a comprehensive line of Tender Assisted DES to be applied not only on fixed platforms and jackets, but also for deeper water operations on TLPs and SPARs. DRILLMEC DES design focuses on the following key advantages and main aspects:

<ul>

<li>Light weight design</li>

<li>Minimized quantity of loads - downt to 3, depending on client's preferences and lifting requirements</li>

<li>Quick and safe rig-up operations</li>

<li>Maximized tripping speed and set-up for offline operations</li>

</ul>

</div>

<div class="last column">

<p class="split">Drilllmec's typical activities for Tender Assisted DES and Modular Rigs include the following:</p>

<ul>

<li>Conceptual design, front-end engineering and detailed engineering</li>

<li>Project Management</li>

<li>Supply of complete drilling equipment, mud equipment and third party equipment</li>

<li>Fabrication and/or construction supervision</li>

<li>Installation, testing, commissioning and site assistance</li>

<li>24/7 After sales assistance and support</li>

</ul>

</div>

Read more

<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-1" class="descr">

<div class="first column">

<strong>DRILLMEC’s GDS Series</strong> is the new generation of Compact Gear Driven Single Speed Drawworks built to improve safety and performance. The compact design makes this product line the state of art to the oil industry for onshore application and excellent for offshore application in case of new installation, refurbishment and upgrading of existing ones.Complete with a modern Automatic Drilling System, PLC based product, AC Motors frequency drive is capable of holding full load at zero speed indefinitely and high safety emergency disc brake system with negative calipers. The package is designed to reduce noise, vibration and maintenance at highest performance level. The GDS Series replaces the MAS Series and it is fully compatible with any rig designs.

<strong>Drillmec GDM Series</strong> Gear Driven Drawworks are the result of years of experience with the main objective of continuous improvement over decades

</div>

<div class="last column">

<p class="split">of innovation. GDM drawworks consists of the following main components: drum, motors, reduction gear, brake and auxiliary brake. Drillmec produces a wide range of drawworks engineered for today’s tough drilling challenges. Like with other Drillmec drilling equipment, our Gear Driven Drawworks can be fitted to all land rigs with power ranging from 1500 to 3000 hp with a nominal depth range from 3500 to 10000 meters (11000 ft to 32000 ft).</p>

<strong>DRILLMEC’s GDS & GDM Series Drawworks for Offshore Application</strong> are developed to offer superior performance for a variety of drilling operations and work environments for both shallow and deep water drilling applications. The GD Series for Offshore Application are characterized by a compact footprint & size, durability, effectiveness, and energy-efficiency even in deep water applications.

</div>

</div>

</div>

</div>

Read more

<div class="first column">

<span style="font-size: 10pt;">Everything about the HH Series is designed for speed, safety and efficiency. You can tell just by looking it is not a conventional rig. </span>

<span style="font-size: 8pt;"><span style="font-size: 10pt;">From it selferecting telescopic mast made from a single powerful hydraulic cylinder to the built-in integrated hydraulic top drive, HH rigs are designed to optimize your drilling plan from top to bottom. Automated systems, centralized control and few rig floor workers combine for a safer and more efficient drilling operation, better performance and reduced costs. The HH Series drilling processes are largely automated and centrally operated from the climate controlled driller’s cabin. Stuck pipe becomes less of an issue with features that allow automatic drilling even with preset WOBs and ROPs or top drive back reaming.</span>

</span>

</div>

<div class="last column"></div>

Read more

<span style="font-size: 10pt;">Everything about the HH Series is designed for speed, safety and efficiency. You can tell just by looking it is not a conventional rig. From it self-erecting telescopic mast made from powerful hydraulic cylinders to the built-in integrated hydraulic top drive, HH rigs are designed to optimize your drilling plan from top to bottom. Automated systems, centralized control and few rig floor workers combine for a safer and more efficient drilling operation, better performance and reduced costs. Compared with rigs of equal power and capability, the HH Series creates a lower weight and smaller footprint reducing also environmental impact. The HH Series answers many demands of the E&P industry; increased productivity, fewer accidents and a reduced impact on the environment. By automating tasks on the floor and mobilizing components for efficiency, the HH Series’ unique design is the shape of things to come.</span>

These are the main features:

<ul>

<li>Hands-off Automatic Handling of Tubulars (DP, Tubing, Casing) using built in: Top Drive – Pipe Handler - Jib Crane – Elevators</li>

<li>Handling ESP Components with full access to the well center</li>

<li>ESP cable guiding & clamping systems for tubing installation</li>

<li>Rig automation to minimize manual involvement in the work</li>

<li>Cyber control cabin with integrated control system</li>

<li>Automated pipe handling including delivery of pipes between pipe rack and the completion rig</li>

<li>Light and compact designs to allow simple and easy application on all different type of platforms</li>

<li>Skidding and rotation system for full well path area covering</li>

<li>Tailor made solutions for all different applications and operations<strong> </strong></li>

</ul>

Read more

<div class="first column">

<ul>

<li>Drillmec’s deep roots in the manufacturing of drilling rigs start back in 1929 and since then continuously improved rig design by raising the pull-up capacity, enhancing safety, optimizing performance and minimizing environmental impact.

Drillmec starting from Massarenti & Branham-design produces a full range of land rig packages to satisfy almost any need with successful achievements all over the world.

Drillmec understands that drilling contractors objectives and conditions are constantly</li>

<li>in flux and require different solutions to achieve results. Drillmec rigs are available in a wide range of specifications in order to fit custom configurations and capabilities</li>

</ul>

</div>

<ul>

<li><strong>Land Rigs - Swing Lift Series</strong>

Drillmec produces swing lift rigs with raising lines or hydraulic cylinders. The Swing Lift Series is designed for fast and safe rig-up and rig-down, minimizing non-productive time.</li>

<li><strong>DM SERIES </strong>( Swing Lift Series, Raising Lines)<strong>

</strong> Swing Lift masts and substructures with hook load capacity from 340 to 907 metric tons (750,000 - 2,000,000 lbs).<strong>HSL SERIES </strong>(Hydraulic Swing Lift Series, Hydraulic Raising)<strong>

</strong>Hydraulic Swing Lift masts and substructures with hook load capacity from 340 to 680 metric tons (750,000 - 1,500,000 lbs).</li>

</ul>

Read more

<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-1" class="descr">

<div class="first column">

Drillmec manufactures derricks and masts for all applications, and, in addition, packages can be furnished with top drives, motion compensators, racking system, pipe handlers, elevators, top mounted flares and all derrick related equipment for complete packages. Drillmec offers a complete range of masts that can be telescopic, bootstrap, cantilever, and barge mounted units. In the design phase, particular care is given to weight, space, environmental loading conditions and operational capacities.

</div>

<div class="last column">

<p class="split">These are the main features of Drillmec derricks:</p>

<ul>

<li>Welded or bolted derricks</li>

<li>Suitable for triple and quadruple stands accommodation</li>

<li>Racking board equipped with racker and stand maker systems</li>

</ul>

</div>

</div>

</div>

</div>

Read more

<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-1" class="descr">

<div class="first column">

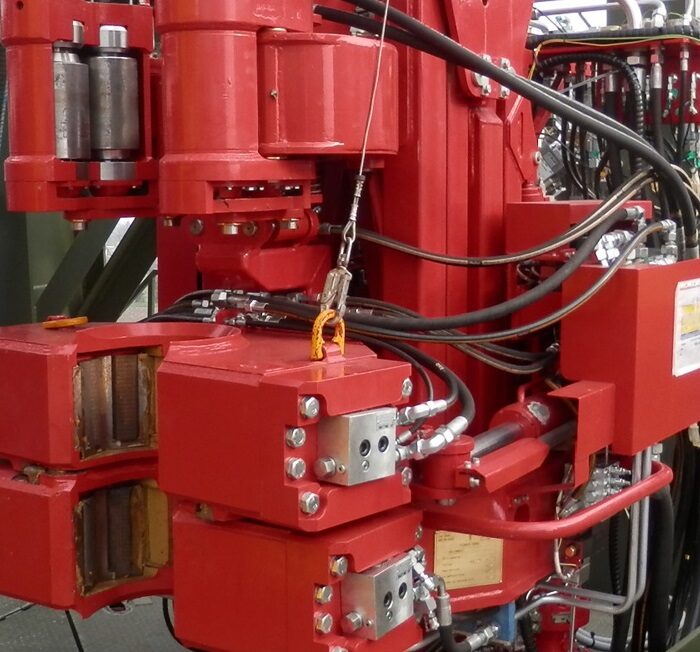

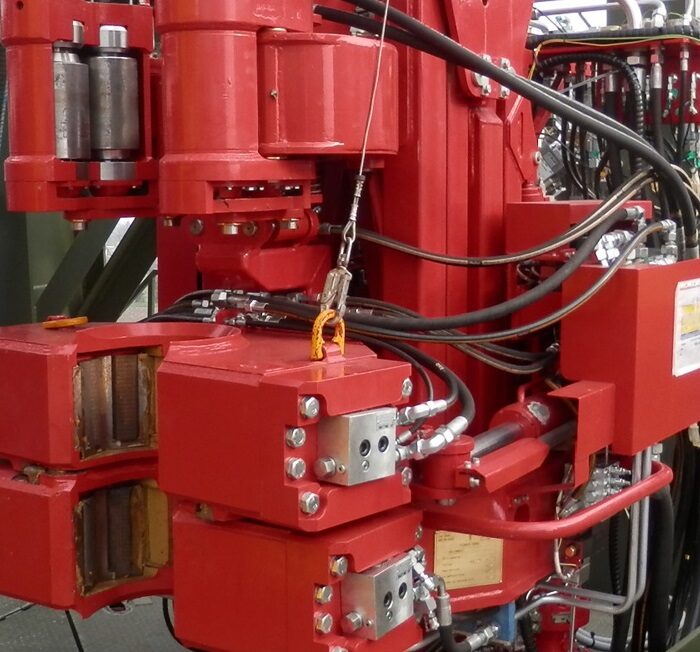

<strong>DRILLMEC's Compact Power Tong</strong> is able to offer high torque performances with very quick operations.

Drillmec PCT system, consist mainly of:

</div>

<div class="last column">

<ul class="split">

<li class="split">Set of hydraulic cylinders for vertical and horizontal power tong moving</li>

<li>Spinning system</li>

<li>Pedestral/Positioning</li>

<li>Rotating clamps</li>

</ul>

</div>

<strong>PCT Series Main features</strong>

</div>

</div>

</div>

<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-2" class="descr">

<div class="first column">

<ul>

<li>Can be installed directly on rig floor through a pedestal, can be powered by a Hydraulic Power Unit (stand alone system) or by the auxiliary rig’s HPU.</li>

<li>Controls are located in the driller cabin and on the drill floor, connected to the PCT by cables, allowing remote operation handling at safe distance<strong> </strong></li>

</ul>

</div>

<div class="last column">

<p class="split"><strong class="split">PCT Series Main Benefits:</strong></p>

<ul>

<li>Controls positioned on the handling arm frame available in case of emergency</li>

<li>Easy installation and handling procedure, two pad eyes rated 17 ton each top mounted for lifting operations</li>

<li>Equipped with one limit switch that stops upper clamp rotation during make-up phase</li>

<li>High torque performance and wide OD range availability</li>

</ul>

</div>

</div>

</div>

</div>

Read more

Every rig operator is looking for greater efficiency and safer operations at the same time. Drillmec automated Pipe Handling Equipment accomplishes both in easy to operate and extremely reliable equipment.

Power Catwalk & Pipe Shuttle

Power Catwalk / Pipe Shuttle are the devices used for moving tubulars in complete safety from pipe racks to drill floor.

Bridge Crane Racker

Bridge Crane Racker is mounted on runway beams installed inside of the derrick, over the racking area. The lifting arm, equipped with a clamp, can be extended into the path of the traveling equipment and can handle various tubular sizes. The arm is equipped with a safety shear pin and safety cable to prevent damage should a collision occur. The racker can move the tubulars from racking board to well center, and viceversa.

The bridge, 200 degree slewing and trolley functions are driven by rack and pinion drives and powered by rig hydraulic power.

The control panels will be integrated into: derrick man cabin, driller’s control panel and driller’s assistant control panel.

The Bridge Racker controls are configured such that the Racker can be run from a joystick controller on the derrick man control cabin or manually with the manually operated hydraulic controls in the derrick man control cabin, should there be any problems with the electrical controls.

The system will be furnished with a complete zone management system to prevent collision between handler elements and travelling equipment.

The Bridge Racker uses electrical components suitable for operation in Zone 2.

Read more