<div class="first column">

Drillmec product line can also offer different auxìliary Equipment, such as:

<strong>Drilling Fluid Equipment – Mud System, Bulk Storage and Transfer, Mud Tanks, Mud Guns, Mud Monitoring, Seawater Cooling Units

</strong>

DRILLMEC designs and manufacture complete mud and bulk systems to be integrated into a complete DRILLMEC drilling package to offer a full integrated solution. DRILLMEC offering and portfolio includes standardized solutions as well as tailor made ones in accordance to specific needs and project requirements.

<strong>Skidding Systems

</strong>

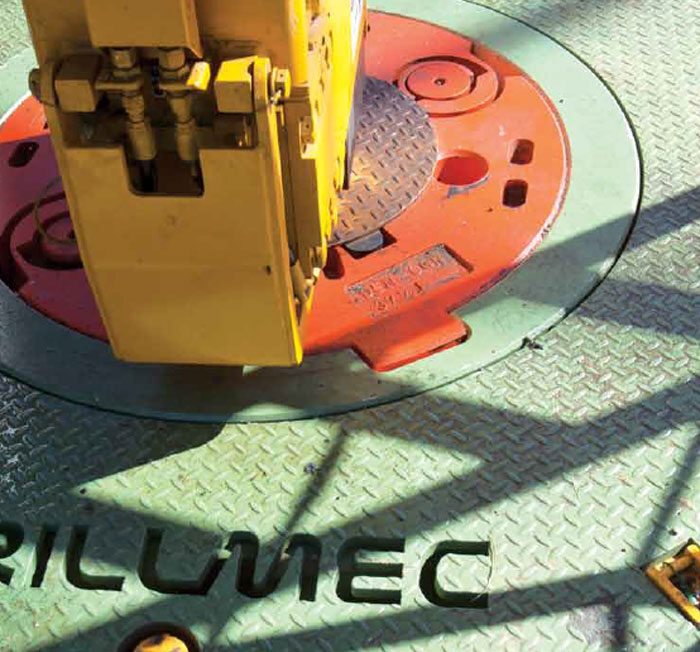

DRILLMEC Skidding Systems are designed and tailor made according to specific drilling rig configuration, operational requirement and overall well slots to be covered.

DRILLMEC Skidding Systems portfolio include the conventional models:Gripper Jack type

<ul>

<li>Ratchet Jack</li>

<li>Lift & Roll</li>

</ul>

Combined with some unconventional skidding solutions for special applications :

<ul>

<li>Walking Systems</li>

<li>Rotating Hydraulic Driven Pivoting Wheels</li>

</ul>

Main characteristics taken into consideration where designing a skidding systems are the following main ones: capping beams size, distance between the wells, directions to cover, capping beams maximum allowable pressure and overall skidding capacity.

<strong>HPU

</strong>

Hydraulic power unit (HPU) is a critical part of a rig and all its operations.

DRILLMEC with its experience in Hydraulic Rigs and Hydraulic Equipmnet is capable to offer a wide range of hydraulic power units suitable to meet any customer application, international standard and capable to feed from individual equipment to complete drilling packages.

<strong>Air Unit</strong>

DRILLMEC air units are designed and tailor made in accordance to package requirements and pneumatic consumers on board of the drilling package.

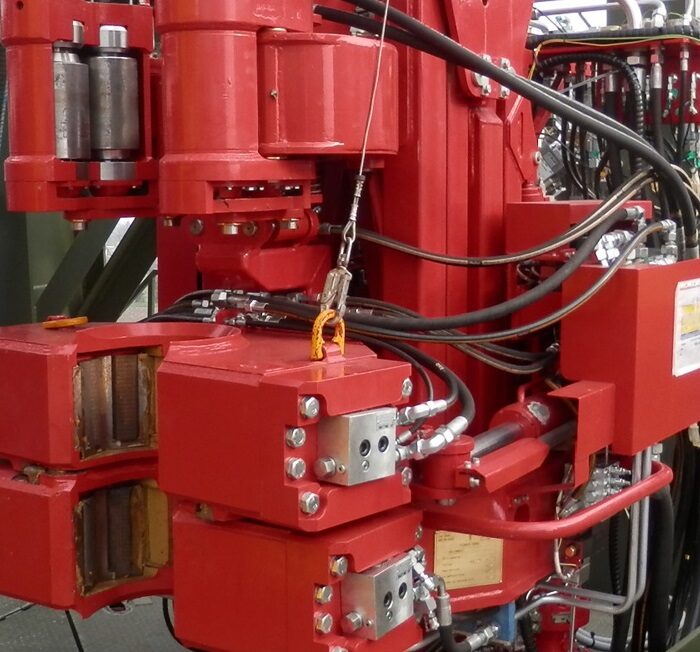

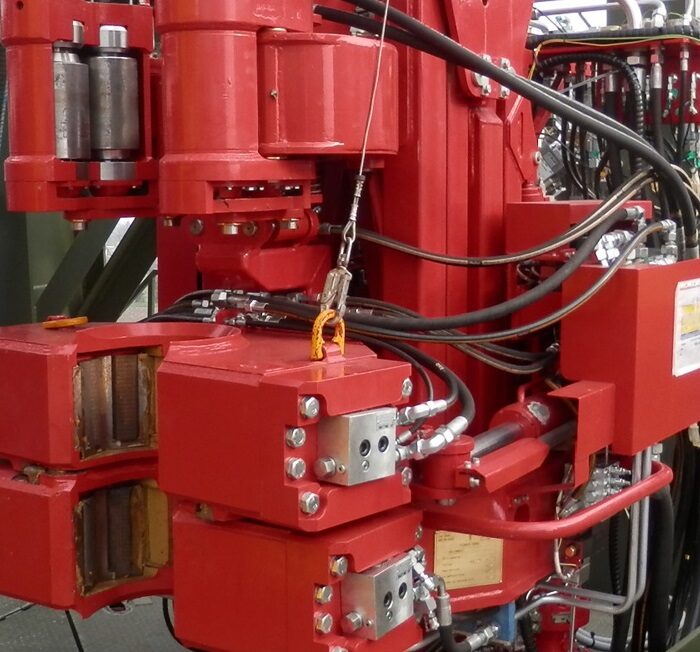

<strong>Hydraulic Cathead</strong>

DRILLMEC Jack type hydraulic cathead system is composed by: hydraulic cylinder with wire line consisting of cylinder with backup post, anchor Adapter,

</div>

<div class="last column">

<p class="split">and wireline assembly.</p>

<strong>Top Drive and Travelling Block Retractable Dolly</strong>

DRILLMEC Dolly and block Retract Systems are designed both Top Drives and Travelling blocks in order to increase tripping speed and optimize drilling efficiency.

The Retractlable Dolly System is a custom designed parking system, specifically engineered to be integrated with derrick structures and drill floor arrangements on offshore rigs.

</div>

Read more

<div class="first column">

Drillmec’s Control Cabins are specifically designed and tailor made for each individual drill floor, from land rig single sit operation up to triple sits control cabins for floaters.

Driller Cabin are equipped with air conditioning system and air pressurizing system and all components inside the cabin are designed for safe-area and ex-proof if necessary.

It is crucial for rig operators and personnel to have full access to interact with the rig during all drilling operations.

DRILLMEC offers also last generation <strong>Cyber Chairs </strong>as an Integrated Drilling Control System allowing the Driller to manage, control and monitor rig floor equipment in four

</div>

<div class="last column">

<p class="split">PC Panels to ensure safe, efficient and seamless operations.</p>

The <strong>Data Mate System (DMS) </strong>provides the rig operator with vital information to manage productivity during drilling and production operations. All the information can be display locally or transmitted to remote for supervisory service or troubleshoorting.

Drillmec’s extensive knowledge and experience with drilling and equipment helped us develop innovative tools that simplifies the operator’s job.

</div>

Read more

<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-1" class="descr">

<div class="first column">

<strong>DRILLMEC’s GDS Series</strong> is the new generation of Compact Gear Driven Single Speed Drawworks built to improve safety and performance. The compact design makes this product line the state of art to the oil industry for onshore application and excellent for offshore application in case of new installation, refurbishment and upgrading of existing ones.Complete with a modern Automatic Drilling System, PLC based product, AC Motors frequency drive is capable of holding full load at zero speed indefinitely and high safety emergency disc brake system with negative calipers. The package is designed to reduce noise, vibration and maintenance at highest performance level. The GDS Series replaces the MAS Series and it is fully compatible with any rig designs.

<strong>Drillmec GDM Series</strong> Gear Driven Drawworks are the result of years of experience with the main objective of continuous improvement over decades

</div>

<div class="last column">

<p class="split">of innovation. GDM drawworks consists of the following main components: drum, motors, reduction gear, brake and auxiliary brake. Drillmec produces a wide range of drawworks engineered for today’s tough drilling challenges. Like with other Drillmec drilling equipment, our Gear Driven Drawworks can be fitted to all land rigs with power ranging from 1500 to 3000 hp with a nominal depth range from 3500 to 10000 meters (11000 ft to 32000 ft).</p>

<strong>DRILLMEC’s GDS & GDM Series Drawworks for Offshore Application</strong> are developed to offer superior performance for a variety of drilling operations and work environments for both shallow and deep water drilling applications. The GD Series for Offshore Application are characterized by a compact footprint & size, durability, effectiveness, and energy-efficiency even in deep water applications.

</div>

</div>

</div>

</div>

Read more

<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-1" class="descr">

<div class="first column">

<strong>DRILLMEC's Compact Power Tong</strong> is able to offer high torque performances with very quick operations.

Drillmec PCT system, consist mainly of:

</div>

<div class="last column">

<ul class="split">

<li class="split">Set of hydraulic cylinders for vertical and horizontal power tong moving</li>

<li>Spinning system</li>

<li>Pedestral/Positioning</li>

<li>Rotating clamps</li>

</ul>

</div>

<strong>PCT Series Main features</strong>

</div>

</div>

</div>

<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-2" class="descr">

<div class="first column">

<ul>

<li>Can be installed directly on rig floor through a pedestal, can be powered by a Hydraulic Power Unit (stand alone system) or by the auxiliary rig’s HPU.</li>

<li>Controls are located in the driller cabin and on the drill floor, connected to the PCT by cables, allowing remote operation handling at safe distance<strong> </strong></li>

</ul>

</div>

<div class="last column">

<p class="split"><strong class="split">PCT Series Main Benefits:</strong></p>

<ul>

<li>Controls positioned on the handling arm frame available in case of emergency</li>

<li>Easy installation and handling procedure, two pad eyes rated 17 ton each top mounted for lifting operations</li>

<li>Equipped with one limit switch that stops upper clamp rotation during make-up phase</li>

<li>High torque performance and wide OD range availability</li>

</ul>

</div>

</div>

</div>

</div>

Read more

Every rig operator is looking for greater efficiency and safer operations at the same time. Drillmec automated Pipe Handling Equipment accomplishes both in easy to operate and extremely reliable equipment.

Power Catwalk & Pipe Shuttle

Power Catwalk / Pipe Shuttle are the devices used for moving tubulars in complete safety from pipe racks to drill floor.

Bridge Crane Racker

Bridge Crane Racker is mounted on runway beams installed inside of the derrick, over the racking area. The lifting arm, equipped with a clamp, can be extended into the path of the traveling equipment and can handle various tubular sizes. The arm is equipped with a safety shear pin and safety cable to prevent damage should a collision occur. The racker can move the tubulars from racking board to well center, and viceversa.

The bridge, 200 degree slewing and trolley functions are driven by rack and pinion drives and powered by rig hydraulic power.

The control panels will be integrated into: derrick man cabin, driller’s control panel and driller’s assistant control panel.

The Bridge Racker controls are configured such that the Racker can be run from a joystick controller on the derrick man control cabin or manually with the manually operated hydraulic controls in the derrick man control cabin, should there be any problems with the electrical controls.

The system will be furnished with a complete zone management system to prevent collision between handler elements and travelling equipment.

The Bridge Racker uses electrical components suitable for operation in Zone 2.

Read more

<div class="first column">

Drillmec rotary table is designed for rough conditions and complies with the strictest approvals for the drilling industry. Drillmec’s rotary table “R Type” are designed, in accordance with the industry standards, for drilling depths up to 30,000 FT and beyond. Driven by electric or hydraulic power, “R Type” are interchangeable with the most popular rotary table brands.

</div>

<div class="last column">

<p class="split">Drillmec’s quality department inspects all phases of manufacture and every item is tested in our premesis before delivery.</p>

</div>

Read more

<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-1" class="descr">

<div class="first column">

<strong>Hydraulic Top Drives</strong>Drillmec manufactures a full range of hydraulic top drives. Drillmec HTD series top drives can be fitted to almost any rig in order to increase the performance and help in operations such as directional or horizontal drilling. Drillmec designs top drive rails and torque tube starting from drawings of the customer rig or from data collected by

</div>

<div class="last column">

<p class="split">our technicians directly on the rig field.

The torque tube provide the connection between the new HTD top drive and the existing rig. The HTD top drive is supplied with an independent hydraulic power pack and controls and with a transportation cradle designed to hold it and help in moving.</p>

</div>

<strong>Electric Top Drives</strong>

</div>

</div>

</div>

<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-2" class="descr">

<div class="first column">

In the oil & gas industry top drive technology is used to increase performance and safety; from Drillmec solid experience in manufacturing hydraulic pipe handling and top drives, we introduce the ETD Series. The Drillmec Electric Top Drive is designed as transportable as well as permanent installed unit for deep drilling rigs with different mast types. The System is powered by an AC motor. The ETD Series is controlled by a separate control panel.

<div class="first column">

The standard Top Drive version includes the following items:

</div>

<div class="last column">

<ul class="split">

<li class="split">Standard washpipe</li>

<li>Link-tilt-system with position monitoring designed for high impacts</li>

<li>Remote-controlled and manual IBOP</li>

<li>Backup Clamp to make up and break the Top Drive drill pipe connection</li>

<li>Guide rail system inducing the torque within the mast</li>

<li>Electrical service loop</li>

<li>Suitable for installation on any kind of mast and derrick</li>

<li>Hanger assembly with integrated Counterbalance cylinders</li>

</ul>

</div>

</div>

</div>

</div>

</div>

Read more

<div class="first column">

<strong>DRILLMEC </strong>offers a complete range of <strong>Triplex Mud Pumps </strong>from 600 hp to 2400 hp diesel or electric AC – DC powered both 5000 and 7500 psi rated.

All the mud pumps can be mounted on an oilfield skid or trailerized in order to favour fast moves.

Before being installed all the single parts are checked and a quality code is assigned. After the final assembly

every mud pump is severely tested in our test area.

</div>

<div class="last column">

<p class="split"><strong class="split">DRILLMEC’s GD Series</strong> is the new generation of Gear Driven<strong> Triplex Mud Pumps</strong> in the ranging from 1600 to 2400 hp for both onshore and offshore drilling operations.</p>

<p class="split">The direct gear driven transmission between the AC motor and the cranshaft together with the top mounted configuration gives to the GD Series Mud Pumps a very compact design despite their high volume and high pressure capabilies.</p>

<strong>GD Series</strong> Triplex Mud Pumps are <strong>equipped with P-Quip </strong>fast release system for valve cover, rod and liner.

The fluid end is suitable for a maximum working pressure of 7500 psi.

</div>

Read more