<div class="first column">

<span style="font-size: 10pt;">Everything about the HH Series is designed for speed, safety and efficiency. You can tell just by looking it is not a conventional rig. </span>

<span style="font-size: 8pt;"><span style="font-size: 10pt;">From it selferecting telescopic mast made from a single powerful hydraulic cylinder to the built-in integrated hydraulic top drive, HH rigs are designed to optimize your drilling plan from top to bottom. Automated systems, centralized control and few rig floor workers combine for a safer and more efficient drilling operation, better performance and reduced costs. The HH Series drilling processes are largely automated and centrally operated from the climate controlled driller’s cabin. Stuck pipe becomes less of an issue with features that allow automatic drilling even with preset WOBs and ROPs or top drive back reaming.</span>

</span>

</div>

<div class="last column"></div>

Read more

<span style="font-size: 10pt;">Everything about the HH Series is designed for speed, safety and efficiency. You can tell just by looking it is not a conventional rig. From it self-erecting telescopic mast made from powerful hydraulic cylinders to the built-in integrated hydraulic top drive, HH rigs are designed to optimize your drilling plan from top to bottom. Automated systems, centralized control and few rig floor workers combine for a safer and more efficient drilling operation, better performance and reduced costs. Compared with rigs of equal power and capability, the HH Series creates a lower weight and smaller footprint reducing also environmental impact. The HH Series answers many demands of the E&P industry; increased productivity, fewer accidents and a reduced impact on the environment. By automating tasks on the floor and mobilizing components for efficiency, the HH Series’ unique design is the shape of things to come.</span>

These are the main features:

<ul>

<li>Hands-off Automatic Handling of Tubulars (DP, Tubing, Casing) using built in: Top Drive – Pipe Handler - Jib Crane – Elevators</li>

<li>Handling ESP Components with full access to the well center</li>

<li>ESP cable guiding & clamping systems for tubing installation</li>

<li>Rig automation to minimize manual involvement in the work</li>

<li>Cyber control cabin with integrated control system</li>

<li>Automated pipe handling including delivery of pipes between pipe rack and the completion rig</li>

<li>Light and compact designs to allow simple and easy application on all different type of platforms</li>

<li>Skidding and rotation system for full well path area covering</li>

<li>Tailor made solutions for all different applications and operations<strong> </strong></li>

</ul>

Read more

<div class="first column">

<ul>

<li>Drillmec’s deep roots in the manufacturing of drilling rigs start back in 1929 and since then continuously improved rig design by raising the pull-up capacity, enhancing safety, optimizing performance and minimizing environmental impact.

Drillmec starting from Massarenti & Branham-design produces a full range of land rig packages to satisfy almost any need with successful achievements all over the world.

Drillmec understands that drilling contractors objectives and conditions are constantly</li>

<li>in flux and require different solutions to achieve results. Drillmec rigs are available in a wide range of specifications in order to fit custom configurations and capabilities</li>

</ul>

</div>

<ul>

<li><strong>Land Rigs - Swing Lift Series</strong>

Drillmec produces swing lift rigs with raising lines or hydraulic cylinders. The Swing Lift Series is designed for fast and safe rig-up and rig-down, minimizing non-productive time.</li>

<li><strong>DM SERIES </strong>( Swing Lift Series, Raising Lines)<strong>

</strong> Swing Lift masts and substructures with hook load capacity from 340 to 907 metric tons (750,000 - 2,000,000 lbs).<strong>HSL SERIES </strong>(Hydraulic Swing Lift Series, Hydraulic Raising)<strong>

</strong>Hydraulic Swing Lift masts and substructures with hook load capacity from 340 to 680 metric tons (750,000 - 1,500,000 lbs).</li>

</ul>

Read more

<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-1" class="descr">

<div class="first column">

Drillmec manufactures derricks and masts for all applications, and, in addition, packages can be furnished with top drives, motion compensators, racking system, pipe handlers, elevators, top mounted flares and all derrick related equipment for complete packages. Drillmec offers a complete range of masts that can be telescopic, bootstrap, cantilever, and barge mounted units. In the design phase, particular care is given to weight, space, environmental loading conditions and operational capacities.

</div>

<div class="last column">

<p class="split">These are the main features of Drillmec derricks:</p>

<ul>

<li>Welded or bolted derricks</li>

<li>Suitable for triple and quadruple stands accommodation</li>

<li>Racking board equipped with racker and stand maker systems</li>

</ul>

</div>

</div>

</div>

</div>

Read more

<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-1" class="descr">

<div class="first column">

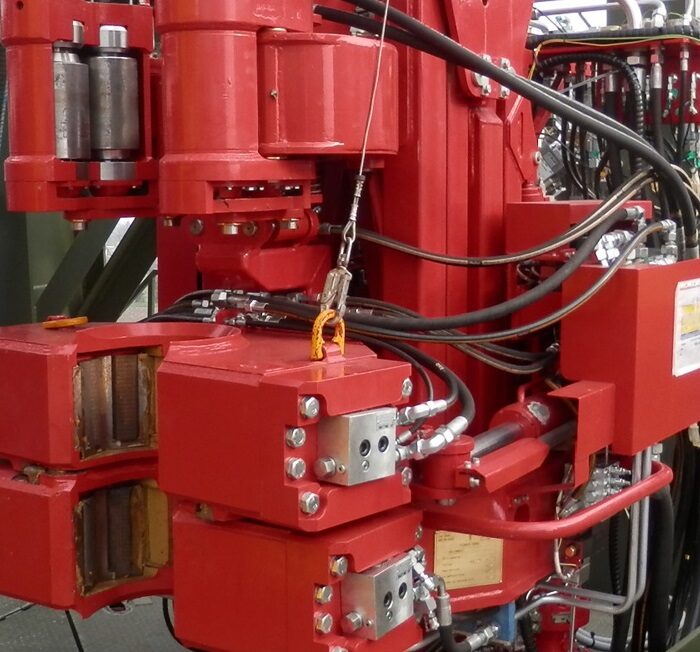

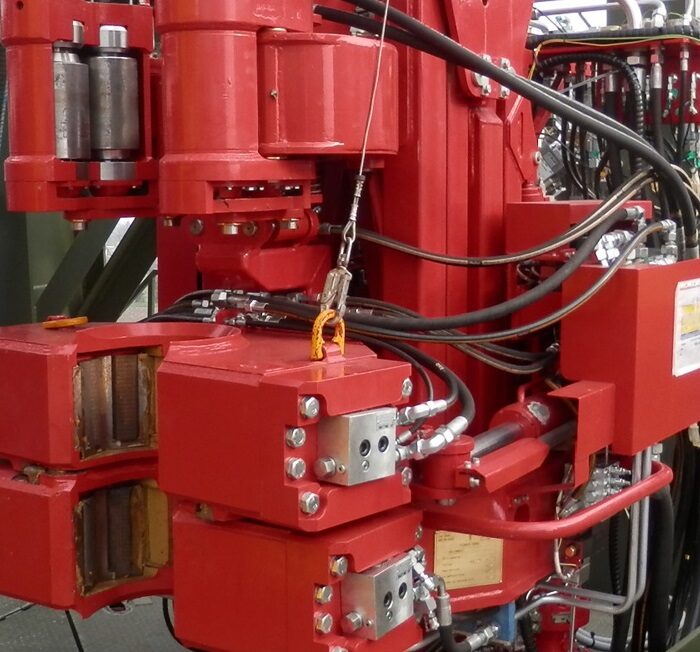

<strong>DRILLMEC's Compact Power Tong</strong> is able to offer high torque performances with very quick operations.

Drillmec PCT system, consist mainly of:

</div>

<div class="last column">

<ul class="split">

<li class="split">Set of hydraulic cylinders for vertical and horizontal power tong moving</li>

<li>Spinning system</li>

<li>Pedestral/Positioning</li>

<li>Rotating clamps</li>

</ul>

</div>

<strong>PCT Series Main features</strong>

</div>

</div>

</div>

<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-2" class="descr">

<div class="first column">

<ul>

<li>Can be installed directly on rig floor through a pedestal, can be powered by a Hydraulic Power Unit (stand alone system) or by the auxiliary rig’s HPU.</li>

<li>Controls are located in the driller cabin and on the drill floor, connected to the PCT by cables, allowing remote operation handling at safe distance<strong> </strong></li>

</ul>

</div>

<div class="last column">

<p class="split"><strong class="split">PCT Series Main Benefits:</strong></p>

<ul>

<li>Controls positioned on the handling arm frame available in case of emergency</li>

<li>Easy installation and handling procedure, two pad eyes rated 17 ton each top mounted for lifting operations</li>

<li>Equipped with one limit switch that stops upper clamp rotation during make-up phase</li>

<li>High torque performance and wide OD range availability</li>

</ul>

</div>

</div>

</div>

</div>

Read more

Every rig operator is looking for greater efficiency and safer operations at the same time. Drillmec automated Pipe Handling Equipment accomplishes both in easy to operate and extremely reliable equipment.

Power Catwalk & Pipe Shuttle

Power Catwalk / Pipe Shuttle are the devices used for moving tubulars in complete safety from pipe racks to drill floor.

Bridge Crane Racker

Bridge Crane Racker is mounted on runway beams installed inside of the derrick, over the racking area. The lifting arm, equipped with a clamp, can be extended into the path of the traveling equipment and can handle various tubular sizes. The arm is equipped with a safety shear pin and safety cable to prevent damage should a collision occur. The racker can move the tubulars from racking board to well center, and viceversa.

The bridge, 200 degree slewing and trolley functions are driven by rack and pinion drives and powered by rig hydraulic power.

The control panels will be integrated into: derrick man cabin, driller’s control panel and driller’s assistant control panel.

The Bridge Racker controls are configured such that the Racker can be run from a joystick controller on the derrick man control cabin or manually with the manually operated hydraulic controls in the derrick man control cabin, should there be any problems with the electrical controls.

The system will be furnished with a complete zone management system to prevent collision between handler elements and travelling equipment.

The Bridge Racker uses electrical components suitable for operation in Zone 2.

Read more

DRILLMEC engineering centres in Italy and the US are able to study tailored solutions starting from off-the-shelf designs to fit with the most demanding purpose and requirements.

DRILLMEC packages can be tailor made and complete with: generators, PCRs, HP & LP Mud / brine system, pipe handling and well control package according to the client’s requirements and operating targets. Also full range of hook loads are available and can be implemented according to project requirements. Custom made modularization for DRILLMEC units are available including a complete package breakdown to a minimum weight of 10 ton per each load.

Read more

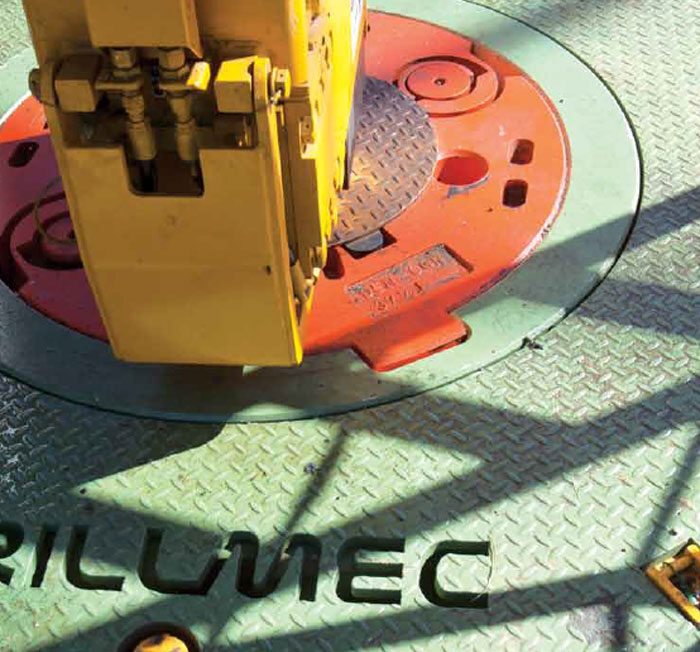

<div class="first column">

Drillmec rotary table is designed for rough conditions and complies with the strictest approvals for the drilling industry. Drillmec’s rotary table “R Type” are designed, in accordance with the industry standards, for drilling depths up to 30,000 FT and beyond. Driven by electric or hydraulic power, “R Type” are interchangeable with the most popular rotary table brands.

</div>

<div class="last column">

<p class="split">Drillmec’s quality department inspects all phases of manufacture and every item is tested in our premesis before delivery.</p>

</div>

Read more

Italdraghe is specialised in the design and production of special purpose dredgers such as Marina Master, able to easily dredge under marinas’ pontoons.

Read more

Italdraghe is specialised in the design and production of special purpose dredgers such as Marina Master, able to easily dredge under marinas’ pontoons.

Read more