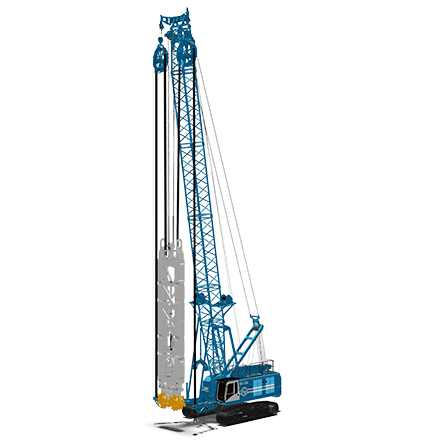

The demand for diaphragm wall equipment suitable to urban areas and the stringent requirement of verticality make the hydromill Cougar a good and easy option to meet the customer’s needs.

The Hose Wheels Design (HWD) is positioned below the cathead so that it can easily follow the hydromill movements with a tensioning and rewinding automatic system. It arises from the need to move simultaneously the hydraulic and bentonite mud circulation hoses to the cutting unit.

The SC-100 Cougar is a compact hydromill equipment optimized for urban areas and low transportation weight (max 50 t; 110,000 lb).

The DMS (Drilling Mate System), developed by Soilmec and installed on all the products of the range, allows the real-time monitoring of all the operating parameters and of the production process, including a dual-axis positioning sensor (triple-axis version as optional) that controls the geometry of the panel with 2D and 3D graphics print out

Read more

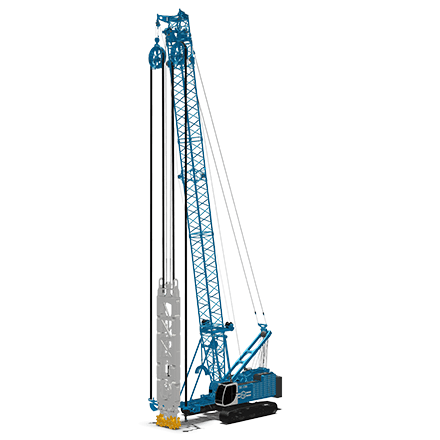

The demand for diaphragm wall equipment suitable to urban areas and the stringent requirement of verticality make the hydromill Cougar a good and easy option to meet the customer’s needs.

The Hose Wheels Design (HWD) is positioned below the cathead so that it can easily follow the hydromill movements with a tensioning and rewinding automatic system. It arises from the need to move simultaneously the hydraulic and bentonite mud circulation hoses to the cutting unit.

The SC-100 Cougar is a compact hydromill equipment optimized for urban areas and low transportation weight (max 50 t; 110,000 lb).

The DMS (Drilling Mate System), developed by Soilmec and installed on all the products of the range, allows the real-time monitoring of all the operating parameters and of the production process, including a dual-axis positioning sensor (triple-axis version as optional) that controls the geometry of the panel with 2D and 3D graphics print out

Read more

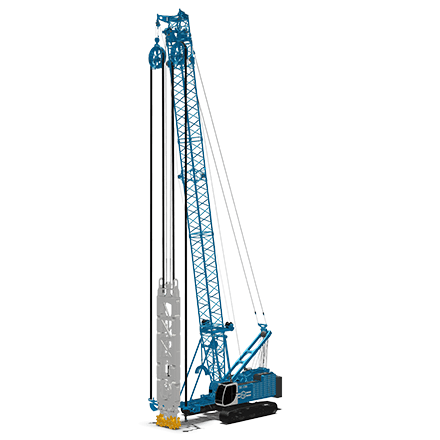

The demand for diaphragm wall equipment suitable to urban areas and the stringent requirement of verticality make the hydromill Cougar a good and easy option to meet the customer’s needs.

The Hose Wheels Design (HWD) is positioned below the cathead so that it can easily follow the hydromill movements with a tensioning and rewinding automatic system. It arises from the need to move simultaneously the hydraulic and bentonite mud circulation hoses to the cutting unit.

The SC-120 Cougar is the high performance HWD series, which excavates more than 60 m of depth with approx. 900 HP ensuring a great level of production rates.

The SC-120, complying with CE requests of EN16228 upon request, has been conceived to offer the best possible safety solutions. The equipment presents a new safe anti-falling system, handrails and ladders, lashing points, remote control boards and reduced speed mode in order to carry out the main assembly/disassembly operations and maintenance procedures in safe conditions.

The DMS (Drilling Mate System), developed by Soilmec and installed on all the products of the range, allows the real-time monitoring of all the operating parameters and of the production process, including a dual-axis positioning sensor (triple-axis version as optional) that controls the geometry of the panel with 2D and 3D graphics print out.

Read more

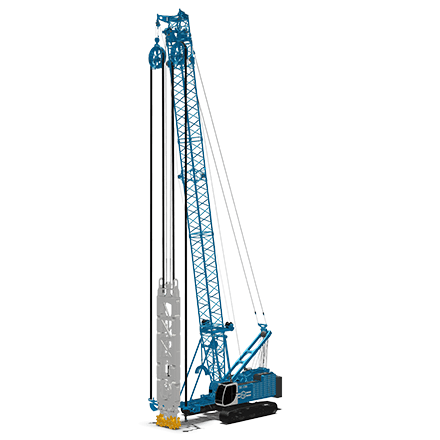

The demand for diaphragm wall equipment suitable to urban areas and the stringent requirement of verticality make the hydromill Cougar a good and easy option to meet the customer’s needs.

The Hose Wheels Design (HWD) is positioned below the cathead so that it can easily follow the hydromill movements with a tensioning and rewinding automatic system. It arises from the need to move simultaneously the hydraulic and bentonite mud circulation hoses to the cutting unit.

The SC-120 Cougar is the high performance HWD series, which excavates more than 60 m of depth with approx. 900 HP ensuring a great level of production rates.

The SC-120, complying with CE requests of EN16228 upon request, has been conceived to offer the best possible safety solutions. The equipment presents a new safe anti-falling system, handrails and ladders, lashing points, remote control boards and reduced speed mode in order to carry out the main assembly/disassembly operations and maintenance procedures in safe conditions.

The DMS (Drilling Mate System), developed by Soilmec and installed on all the products of the range, allows the real-time monitoring of all the operating parameters and of the production process, including a dual-axis positioning sensor (triple-axis version as optional) that controls the geometry of the panel with 2D and 3D graphics print out.

Read more