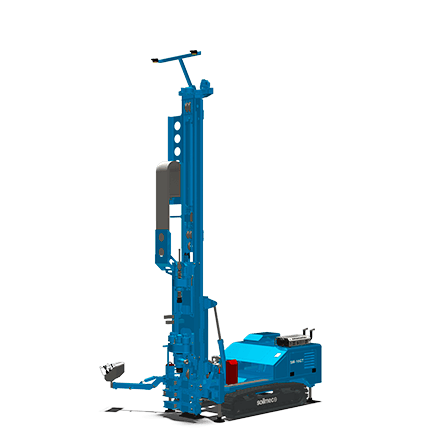

The new<strong> SM-10GT</strong> is a hydraulic drilling rig designed specifically for geothermal drilling.

The fixed kinematic mechanism, wide section mast, and the pull-push system with a 120 kN hydraulic cylinder means drilling deep, precise bores.

The rubber tracked undercarriage and low specific pressure on the ground make this machine ideal for operating in gardens and private courtyards, typical in this kind of application, reducing the impact of the site.

The drilling rig has a hydraulic clamp and breaker suitable for breaking drilling rods and an additional support for manoeuvres during feeding and recovery of the casings.

The drilling battery loading (rods and casings) is fast and safe thanks to a special winch system with magnetic lifting.

Read more

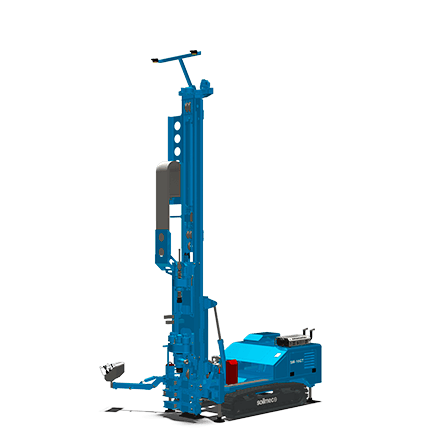

<strong>SM-16GT </strong>responds to the demand of geothermal systems drilling between 100 and 250 metres.

The equipment's characteristics mean it can satisfy 70% of demand from the low-enthalpy geothermal sector. The compact drilling rig has a rubber tracked, 2300 mm-wide carriage and very low ground bearing pressure (0.65 Kg/cm2), thereby minimising damage to private property (gardens and courtyards) where domestic geothermal energy is used.

The drilling rig is equipped with fixed kinematic mechanism with a wide section mast, half-cylinder pull/push and a 19.5 ton pull capacity and 9.8 ton push power.

The rig is designed for rapid manoeuvring (0.2÷0,6 m/sec) and has a 200 kW, 2400 rpm diesel engine adapted to power the double rotary (upper 1100 daNm - bottom 3200 daNm), triple clamp and magnetic loading system to simultaneously manoeuvre rods/casings.

To keep weight to a minimum the drilling rig is not fitted with heavy and bulky casing/rod storage and is instead accompanied by an autonomous motorised rack system during operation.

Read more