The <strong>SF-65 </strong>drilling rig, is the evolution of the already existing equipment dedicated to Continuous Flight Auger drilling technique.

The upper structure of the <strong>SF-65 </strong>is mounted on Soilmec base carrier and has been designed to perform:

- <a href="http://www.soilmec.com/en/products/cfa_piling_rigs/viewdoc.asp?co_id=3600"><strong>CFA </strong></a>(Continuous Flight Auger) piles by means of long auger string.

The <strong>SF-65 </strong>is equipped with the DRILLING MATE SYSTEM (DMS) on 12' touch screen for monitoring and control of the rig performances and operating parameters.

Read more

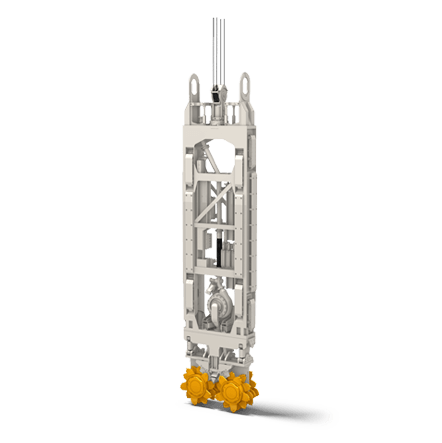

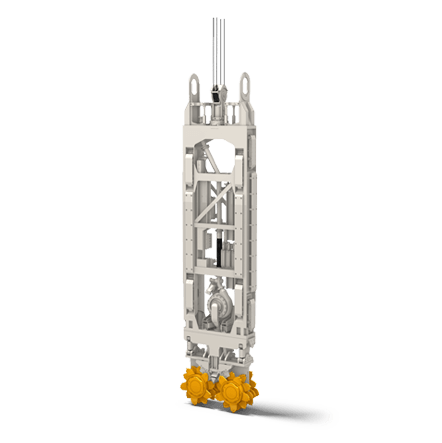

The hydromill module is constituted by a heavy steel frame on which two milling drums and a centrifugal mud pump are mounted. In order to correct the module verticality deviation, 12 independent mobile flaps are positioned on the module surface. Furthermore, a simultaneous or independent tilting plate can be installed as optional for the best verticality correction, especially in case of leaned layers of rock. All Soilmec modules are set with a 2D or 3D sensor developed for the module positioning control, which is managed by the Hydromill DMS.

Soilmec has designed all its modules with a rotation system conceived for T-panel execution or for other module orientations. This specific feature gives the possibility to facilitate the job site operations, leading to a reduction in terms of cost and time.

The 30 t class module is especially designed for Cougar version and urban job sites. It can be fitted with a cutting unit up to 102 kNm torque in order to cover the major requests in terms of panel dimensions and soil stratigraphy. The module rotation system is included as a standard.

Read more

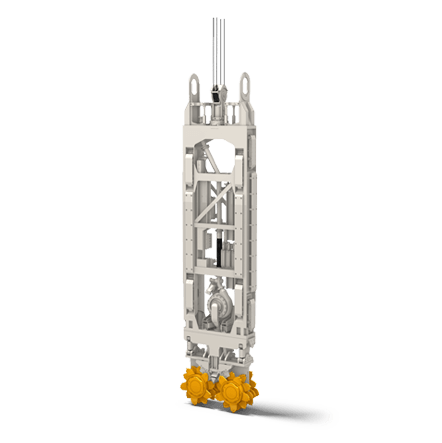

The hydromill module is constituted by a heavy steel frame on which two milling drums and a centrifugal mud pump are mounted. In order to correct the module verticality deviation, 12 independent mobile flaps are positioned on the module surface. Furthermore, a simultaneous or independent tilting plate can be installed as optional for the best verticality correction, especially in case of leaned layers of rock. All Soilmec modules are set with a 2D or 3D sensor developed for the module positioning control, which is managed by the Hydromill DMS.

Soilmec has designed all its modules with a rotation system conceived for T-panel execution or for other module orientations. This specific feature gives the possibility to facilitate the job site operations, leading to a reduction in terms of cost and time.

The 30 t class module is especially designed for Cougar version and urban job sites. It can be fitted with a cutting unit up to 102 kNm torque in order to cover the major requests in terms of panel dimensions and soil stratigraphy. The module rotation system is included as a standard.

Read more

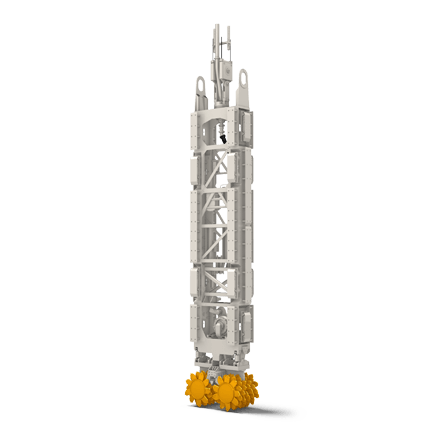

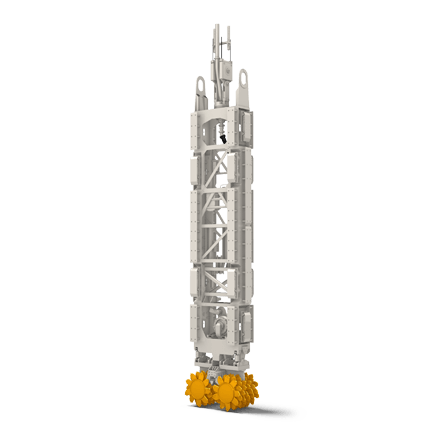

The hydromill module is constituted by a heavy steel frame on which two milling drums and a centrifugal mud pump are mounted. In order to correct the module verticality deviation, 12 independent mobile flaps are positioned on the module surface.

Furthermore, a simultaneous or independent tilting plate can be installed as optional for the best verticality correction, especially in case of leaned layers of rock. All Soilmec modules are set with a 2D or 3D sensor developed for the module positioning control, which is managed by the Hydromill DMS.

Soilmec has designed all its modules with a rotation system conceived for T-panel execution or for other module orientations. This specific feature gives the possibility to facilitate the job site operations, leading to a reduction in terms of cost and time.

The 40 t class module is suggested for medium-high depth projects. Its body length and weight guarantee a high verticality level and panel dimensions up to 3200x1800 mm. The high torque cutting unit (up to 153 kNm) can be installed.

The module rotation system is included as a standard

Read more

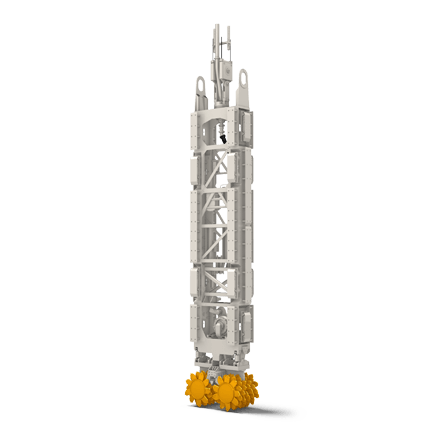

The hydromill module is constituted by a heavy steel frame on which two milling drums and a centrifugal mud pump are mounted. In order to correct the module verticality deviation, 12 independent mobile flaps are positioned on the module surface.

Furthermore, a simultaneous or independent tilting plate can be installed as optional for the best verticality correction, especially in case of leaned layers of rock. All Soilmec modules are set with a 2D or 3D sensor developed for the module positioning control, which is managed by the Hydromill DMS.

Soilmec has designed all its modules with a rotation system conceived for T-panel execution or for other module orientations. This specific feature gives the possibility to facilitate the job site operations, leading to a reduction in terms of cost and time.

The 40 t class module is suggested for medium-high depth projects. Its body length and weight guarantee a high verticality level and panel dimensions up to 3200x1800 mm. The high torque cutting unit (up to 153 kNm) can be installed.

The module rotation system is included as a standard

Read more

The hydromill module is constituted by a heavy steel frame on which two milling drums and a centrifugal mud pump are mounted. In order to correct the module verticality deviation, 12 independent mobile flaps are positioned on the module surface.

Furthermore, a simultaneous or independent tilting plate can be installed as optional for the best verticality correction, especially in case of leaned layers of rock. All Soilmec modules are set with a 2D or 3D sensor developed for the module positioning control which is managed by the Hydromill DMS.

Soilmec has designed all its modules with a rotation system conceived for T-panel execution or for other module orientations. This specific feature gives the possibility to facilitate the job site operations, leading to a reduction in terms of cost and time.

The 50 t class module is conceived for special projects. Its body length and weight guarantee a high verticality level and panel dimensions up to 3200x2000 mm in different soil conditions and at the highest depths (up to 250 m).

The module rotation system is included as a standard

Read more

The hydromill module is constituted by a heavy steel frame on which two milling drums and a centrifugal mud pump are mounted. In order to correct the module verticality deviation, 12 independent mobile flaps are positioned on the module surface.

Furthermore, a simultaneous or independent tilting plate can be installed as optional for the best verticality correction, especially in case of leaned layers of rock. All Soilmec modules are set with a 2D or 3D sensor developed for the module positioning control which is managed by the Hydromill DMS.

Soilmec has designed all its modules with a rotation system conceived for T-panel execution or for other module orientations. This specific feature gives the possibility to facilitate the job site operations, leading to a reduction in terms of cost and time.

The 50 t class module is conceived for special projects. Its body length and weight guarantee a high verticality level and panel dimensions up to 3200x2000 mm in different soil conditions and at the highest depths (up to 250 m).

The module rotation system is included as a standard

Read more

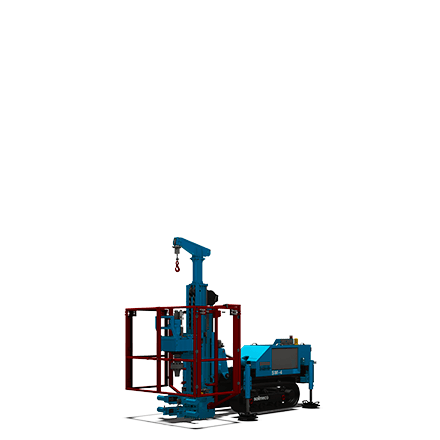

<strong>SM-4</strong> is a new drilling machine featuring a <strong>separate power pack</strong> and the same movements of its larger sister, the SM-5. It has two different engine sizes available: 115 kW and 110 kW respectively (diesel and electrical).

Among the many options the most interesting one is certainly the <strong>LHR kit </strong>(Low Head Room) suitable for 600 mm diameters auger drilling, with cased pilot hole.

Read more

<strong>SM-4</strong> is a new drilling machine featuring a <strong>separate power pack</strong> and the same movements of its larger sister, the SM-5. It has two different engine sizes available: 115 kW and 110 kW respectively (diesel and electrical).

Among the many options the most interesting one is certainly the <strong>LHR kit </strong>(Low Head Room) suitable for 600 mm diameters auger drilling, with cased pilot hole.

Read more

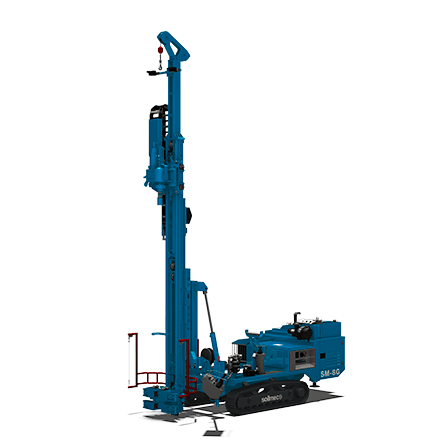

The<strong> new SM-5</strong> is a compact drill rig weighting 5.6 tons, available both with a combined kinematic mechanism that includes a telescopic arm, a +/- 90° tilting and a slew ring on mast (standard version), and in the <strong>G version</strong> that features a fixed kinematic mechanism and coring rotary, for soil-investigation.

The significant installed power, 72 kW, achieves high performance despite small dimensions, thanks to a wide rotary selection with torque values ranging between 690 daNm and 2100 daNm.

Read more

The<strong> new SM-5</strong> is a compact drill rig weighting 5.6 tons, available both with a combined kinematic mechanism that includes a telescopic arm, a +/- 90° tilting and a slew ring on mast (standard version), and in the <strong>G version</strong> that features a fixed kinematic mechanism and coring rotary, for soil-investigation.

The significant installed power, 72 kW, achieves high performance despite small dimensions, thanks to a wide rotary selection with torque values ranging between 690 daNm and 2100 daNm.

Read more

Designed mainly for geognostic use, it can be used for vertical drilling micropiles or inclined ± 13°.

<strong>Main features:</strong>

- Rotation head with 6 ratio gearbox

- Fixed kinetic mechanism

<strong>Optional: </strong>

- Jet-Grouting kit for treatments up to 12 m

- Mud pump screw type and triplex type fitted on board

- Wire-line winch

- Slew ring for inclinated drilling holes

Read more