DESCRIPTION AND APPLICATION

SD desanders that are manufactured by S.A.I.C.I. are particularly designed to treat betonite mud used in drilling and excavating operations with machines equipped with rotating drills or bucket and with forward of reverse circulation. Betonite mud is treated and washed by separating them from solid polluting matters such as: sands, clays, slimes and organic matters. The first treatment – i.e. roughing – is carried out on the steel screen whereby parts exceeding 8 mm are separated; then mud is stored in the tank and from here it is sucked by the pump and conveyed to the hydrocyclone. Here all particles with granulometry exceeding 40/50 micron are separate. All elements subject to wear are made of special wear-resistant materials that are type selected and tested;

| TYPE | SD1000 HP | SD1500 HP | SD2000 HP | SD2500 HP | SD4000 HP | SD5000 HP | |

| Output | [m/h] | 70 | 90 | 140 | 180 | 250/300 | 450/500 |

| Cut Point d50 | [μm] | 45 | 45 | 45 | 45 | 45 | 45 |

| Installed Power | [Kw] | NA | NA | NA | NA | NA | NA |

| Tank Capacity | [m3] | NA | NA | NA | NA | NA | NA |

| Main Screen | [m2] | NA | NA | NA | NA | NA | NA |

| Secondary Screen | [m2] | NA | NA | NA | NA | NA | NA |

| Hydrociclone | NA | NA | NA | NA | NA | NA | |

| Length | [m] | NA | NA | NA | NA | NA | NA |

| Width | [m] | NA | NA | NA | NA | NA | NA |

| Height | [m] | NA | NA | NA | NA | NA | NA |

| Weight | [Kg] | NA | NA | NA | NA | NA | NA |

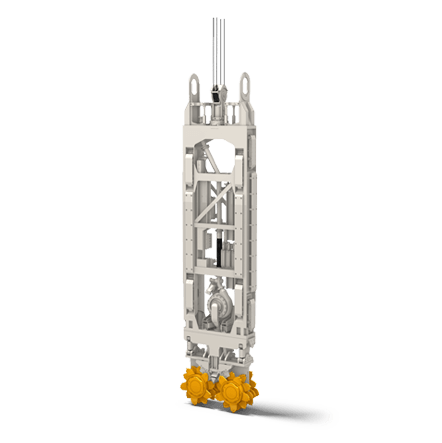

Diagram of the one-step desanders

Reviews

There are no reviews yet.