1- Key features of Italdraghe dredgers :-

– Up-to-date yet easy to operate

– Easy to maintain

– Centrally controlled by just one operator

– Spacious, sound-proofed control cabin with 360° vision

– Powerful, reliable pumps able to discharge over great distances

– Spacious engine room with all round access to equipment

– Cutter heads with replaceable teeth

– Customised to specific client requirements

– Dismountable for easy transport – Use of well-known branded components

Read more

<div class="first column">

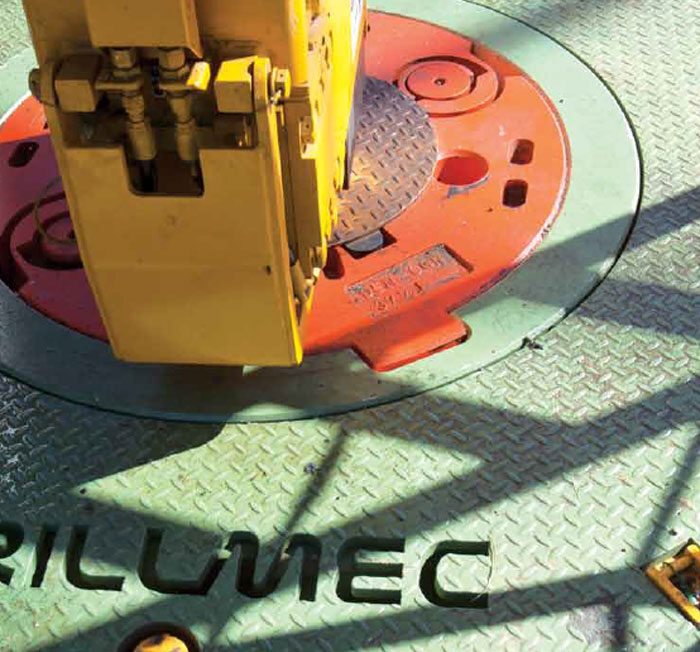

Drillmec’s Control Cabins are specifically designed and tailor made for each individual drill floor, from land rig single sit operation up to triple sits control cabins for floaters.

Driller Cabin are equipped with air conditioning system and air pressurizing system and all components inside the cabin are designed for safe-area and ex-proof if necessary.

It is crucial for rig operators and personnel to have full access to interact with the rig during all drilling operations.

DRILLMEC offers also last generation <strong>Cyber Chairs </strong>as an Integrated Drilling Control System allowing the Driller to manage, control and monitor rig floor equipment in four

</div>

<div class="last column">

<p class="split">PC Panels to ensure safe, efficient and seamless operations.</p>

The <strong>Data Mate System (DMS) </strong>provides the rig operator with vital information to manage productivity during drilling and production operations. All the information can be display locally or transmitted to remote for supervisory service or troubleshoorting.

Drillmec’s extensive knowledge and experience with drilling and equipment helped us develop innovative tools that simplifies the operator’s job.

</div>

Read more

Every rig operator is looking for greater efficiency and safer operations at the same time. Drillmec automated Pipe Handling Equipment accomplishes both in easy to operate and extremely reliable equipment.

Power Catwalk & Pipe Shuttle

Power Catwalk / Pipe Shuttle are the devices used for moving tubulars in complete safety from pipe racks to drill floor.

Bridge Crane Racker

Bridge Crane Racker is mounted on runway beams installed inside of the derrick, over the racking area. The lifting arm, equipped with a clamp, can be extended into the path of the traveling equipment and can handle various tubular sizes. The arm is equipped with a safety shear pin and safety cable to prevent damage should a collision occur. The racker can move the tubulars from racking board to well center, and viceversa.

The bridge, 200 degree slewing and trolley functions are driven by rack and pinion drives and powered by rig hydraulic power.

The control panels will be integrated into: derrick man cabin, driller’s control panel and driller’s assistant control panel.

The Bridge Racker controls are configured such that the Racker can be run from a joystick controller on the derrick man control cabin or manually with the manually operated hydraulic controls in the derrick man control cabin, should there be any problems with the electrical controls.

The system will be furnished with a complete zone management system to prevent collision between handler elements and travelling equipment.

The Bridge Racker uses electrical components suitable for operation in Zone 2.

Read more

<div class="first column">

Drillmec rotary table is designed for rough conditions and complies with the strictest approvals for the drilling industry. Drillmec’s rotary table “R Type” are designed, in accordance with the industry standards, for drilling depths up to 30,000 FT and beyond. Driven by electric or hydraulic power, “R Type” are interchangeable with the most popular rotary table brands.

</div>

<div class="last column">

<p class="split">Drillmec’s quality department inspects all phases of manufacture and every item is tested in our premesis before delivery.</p>

</div>

Read more

Reviews

There are no reviews yet.