| Power Supply: 12 – 24 VDC or 24 VAC | Retrieving data using the MEMOBLOC or by the internet (MEMOTEL option, MEMOSERV service) |

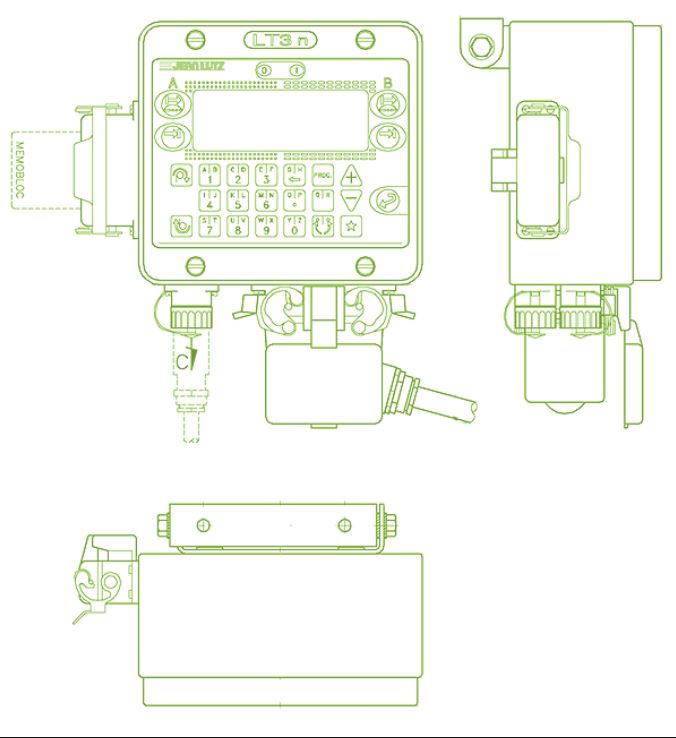

| Dimensions (LT3): 200 x 186 x 107 mm | Dimensions (CL88): 331 x 327 x 268 mm |

| Weight: 4kg (LT3), 8kg (CL88) | Temperature range: -20C / +75 |

| Internal memory (flash memory) | External memory (MEMOBLOC card) |

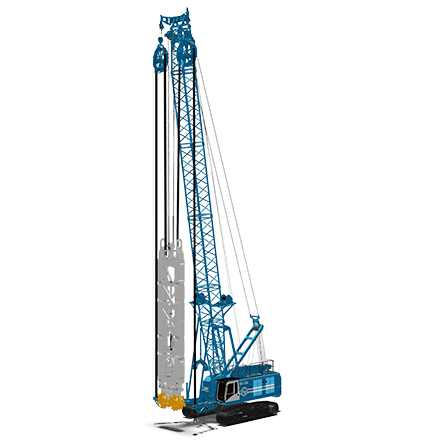

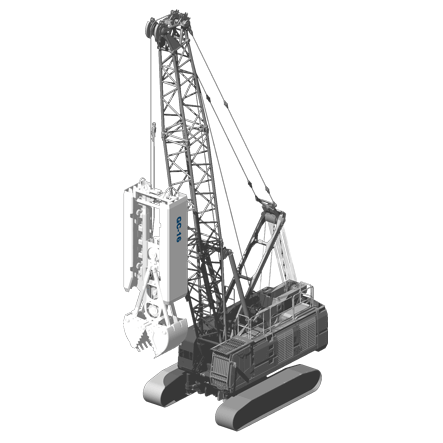

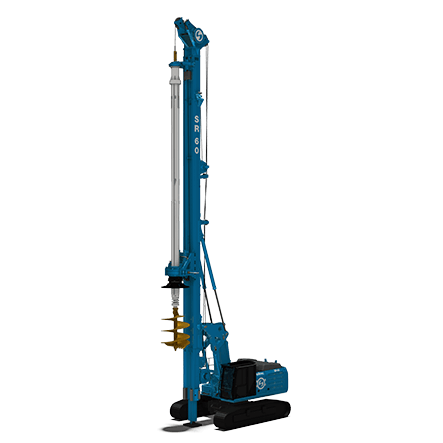

LT3 – CL88

Description

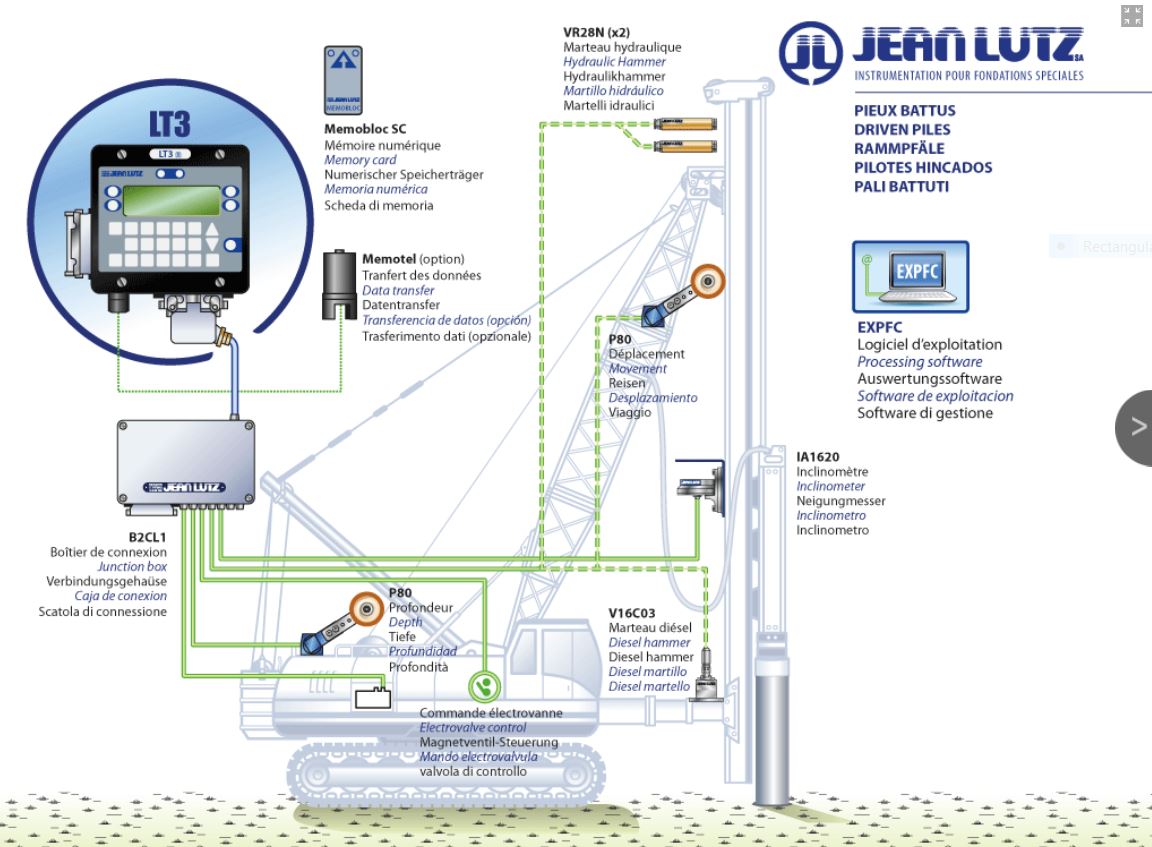

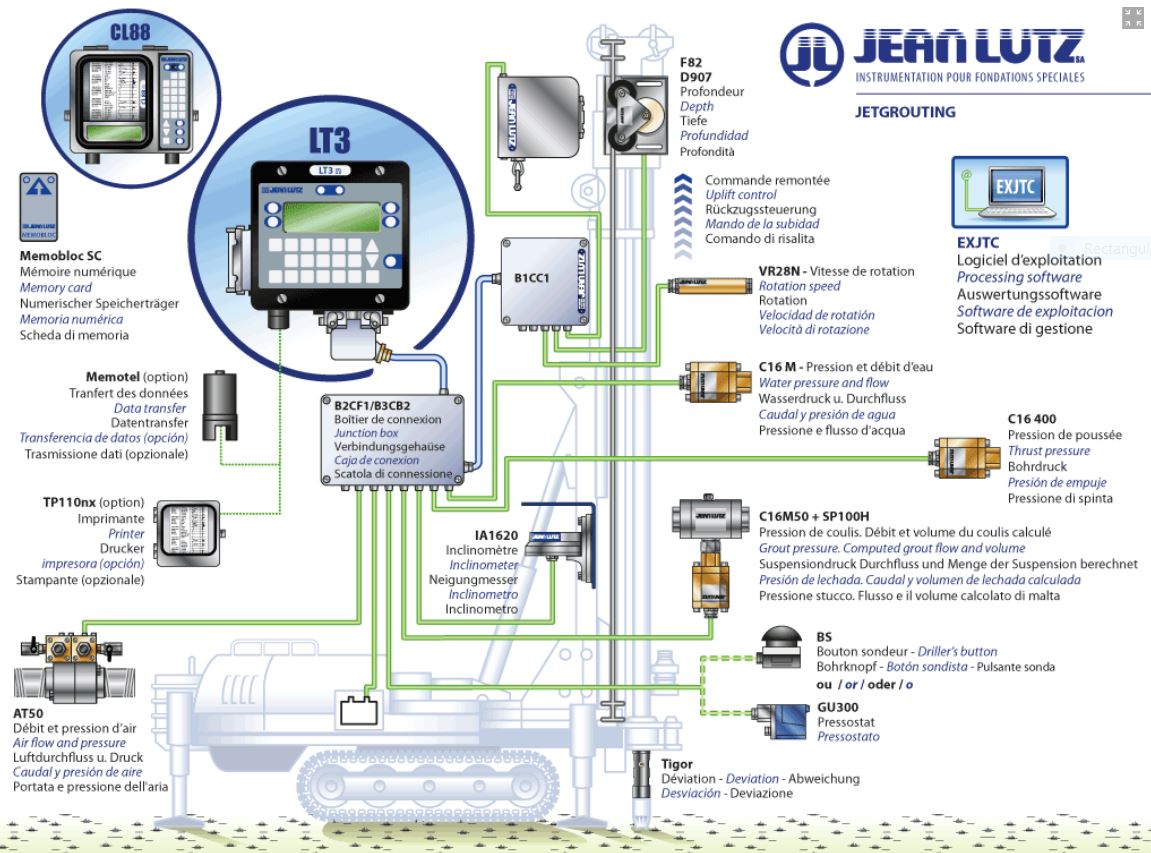

The LT3Nx is an instrument used to measure and record parameters for various specialist foundation processes. Data are recorded and can be transferred directly via the MEMOBLOC memory cards. The CL88 is a drilling parameter measuring and recording instrument. Enclosed in a rugged rustproof metal housing that is sealed against runoff water, it can be used to print out parameters directly. Data are recorded and can be transferred directly via the MEMOBLOC memory cards.

Processes

- Compaction injection.

- Soilmixing.

- Injection.

- Hammered piles.

- Jetgrouting.

- Vibratory pile driving.

- Vibrocompaction.

- Lugeon testing.

.

.

Reviews

There are no reviews yet.