Mud Line

Soilmec offer a machine, a technology and a solution to meet foundation needs. A comprehensive and technologically advanced jobsite, enriched by IPC technology with highly performing auxiliary equipment and accessories in a Mud product line dedicated to the use of bentonite and slurry.

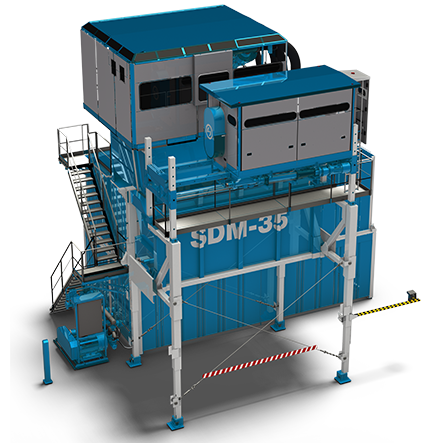

- Mud treatment unit

- Centrifugal self-priming pumps

- Mixers

- Desanders

Categories: Ancillaries, Piling & Foundation Machinery, Soilmec

Related products

-

SH-40

The hydromill module is constituted by a heavy steel frame on which two milling drums and a centrifugal mud pump are mounted. In order to correct the module verticality deviation, 12 independent mobile flaps are positioned on the module surface. Furthermore, a simultaneous or independent tilting plate can be installed as optional for the best verticality correction, especially in case of leaned layers of rock. All Soilmec modules are set with a 2D or 3D sensor developed for the module positioning control, which is managed by the Hydromill DMS. Soilmec has designed all its modules with a rotation system conceived for T-panel execution or for other module orientations. This specific feature gives the possibility to facilitate the job site operations, leading to a reduction in terms of cost and time. The 40 t class module is suggested for medium-high depth projects. Its body length and weight guarantee a high verticality level and panel dimensions up to 3200x1800 mm. The high torque cutting unit (up to 153 kNm) can be installed. The module rotation system is included as a standardRead more -

SF-50

The<strong> SF-50 </strong>drilling rig, is the evolution of the already existing equipment dedicated to Continuous Flight Auger drilling technique. The upper structure of the <strong>SF-50 </strong>is mounted on Soilmec base carrier and has been designed to perform: - <a href="http://www.soilmec.com/en/products/cfa_piling_rigs/viewdoc.asp?co_id=3600">CFA</a> (Continuous Flight Auger) piles by means of long auger string. The <strong>SF-50</strong> is equipped with the DRILLING MATE SYSTEM (DMS) on 12' touch screen for monitoring and control of the rig performances and operating parameters.Read more -

SR-145

Soilmec rigs are self-mounting, easily transportable and designed to giving the best drilling solutions. The hydraulic drilling rig <strong>SR-145 </strong>has been specially designed for suiting the following applications: - <strong>LDP</strong> cased bore piles with casing driven directly by rotary head or optionally by casing oscillator powered by the base carrier itself; - <strong>LDP</strong> deep uncased bored piles stabilized by drilling fluid or dry hole; - <strong>CFA</strong> (Continuous Flight Auger) piles by means of long auger string; - <strong>CAP</strong> (Cased Augered Piles) piles with double independent rotary system; - <strong>DP</strong> (Displacement Piles) /<strong> TCT </strong>(traction compacting tool); - <strong>TJ</strong> (Turbojet®) / <strong>TTJ</strong> (Twin Shaft Turbojet) - soil consolidation; The <strong>SR-145 </strong>is equipped with the DRILLING MATE SYSTEM (DMS) on 12' touch screen for monitoring and control of the rig performances and operating parameters.Read more -

SR-95

Soilmec rigs are self-mounting, easily transportable and designed to giving the best drilling solutions. The hydraulic drilling rig <strong>SR-95 </strong>has been specially designed for suiting the following applications: - <strong>LDP</strong> cased bore piles with casing driven directly by rotary head or optionally by casing oscillator powered by the base carrier itself; - <strong>LDP</strong> deep uncased bored piles stabilized by drilling fluid or dry hole; - <strong>CFA</strong> (Continuous Flight Auger) piles by means of long auger string; - <strong>CAP</strong> (Cased Augered Piles) piles with double independent rotary system; - <strong>DP</strong> (Displacement Piles) /<strong> TCT </strong>(traction compacting tool); - <strong>TJ</strong> (Turbojet®) / <strong>TTJ</strong> (Twin Shaft Turbojet) - soil consolidation; - <strong>RCDS</strong> (Reverse Circulation Drilling System) on demand. The <strong>SR-95 </strong>is equipped with the DRILLING MATE SYSTEM (DMS) on 12' touch screen for monitoring and control of the rig performances and operating parameters.Read more

Reviews

There are no reviews yet.