- Features of the DIALOG data logger:10 inches colour touch screen

- Graphical screen : 3 graphics curves at a time (up to 6 possible), drag and drop allows to drag a parameter on the desired zone.

- Multi-process: by simply selecting the type of work (CFA,JET, SMX, Injections, Vibro … more than 30 processes) the DIALOG will adapt menus, screens, as well as all the functions to the selected process and ensures the proper execution of work monitoring.

- Remote possibility to examine the status of the DIALOG in real-time, data recovery at the end of the pile, display real-time on the screen, review the configuration of the DIALOG, prepare list of jobs …

- Built in GPS

- GPS Positioning: connection for an external high precision GPS (Antoise)

- Automation: various advanced control functions that help the operator to do the perfect job.

- Large Internal memory.

- USB adapter for data transfer.

- Modular with sensor connection boxes (modules) that can be cascaded (expandable) to add new measures sensors to the system.

- 3G Ready allow to remotely follow job site, trouble shoot, pre load the data.

- Double registering system (the DIALOG can register data each cm and each second).

- Possibility to register measures following external triggers (pressure value, station accomplished …)

- Bus system for sensor connection that allows an almost unlimited numbers of sensors and a high flexibility.

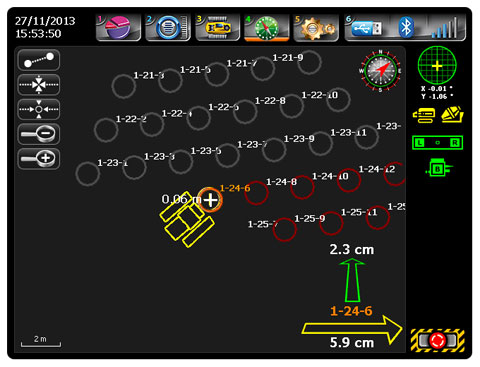

Positioning

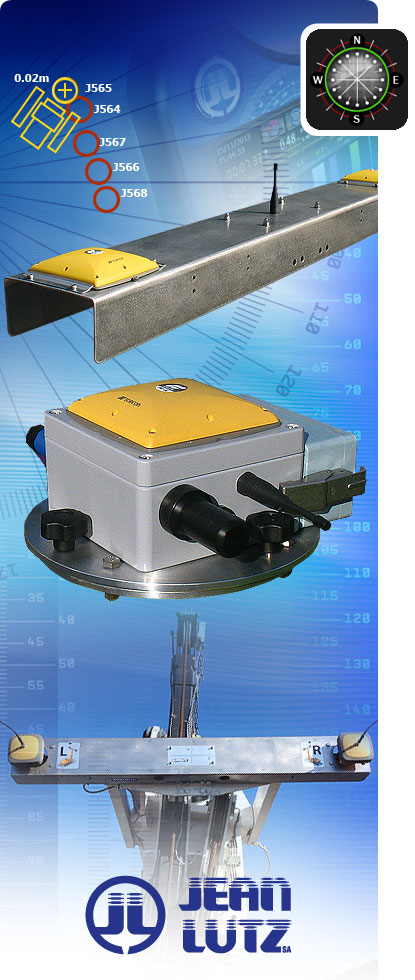

The ANTOISE sensor measures the inclination, orientation and positioning with an accuracy of 3 cm (within 1 inch).

It is composed of three GPS receivers in 2 units, one “base” GPS receiver positioned on a point of exact known coordinates.

It corrects the measurement of a second unit, the GPS “machine.” It is composed of a metal support equipped with 2 receivers and a case containing the electronic computing. One of the receivers is used as the positioning reference, the other to determine the orientation; the assembly is placed on the mast.