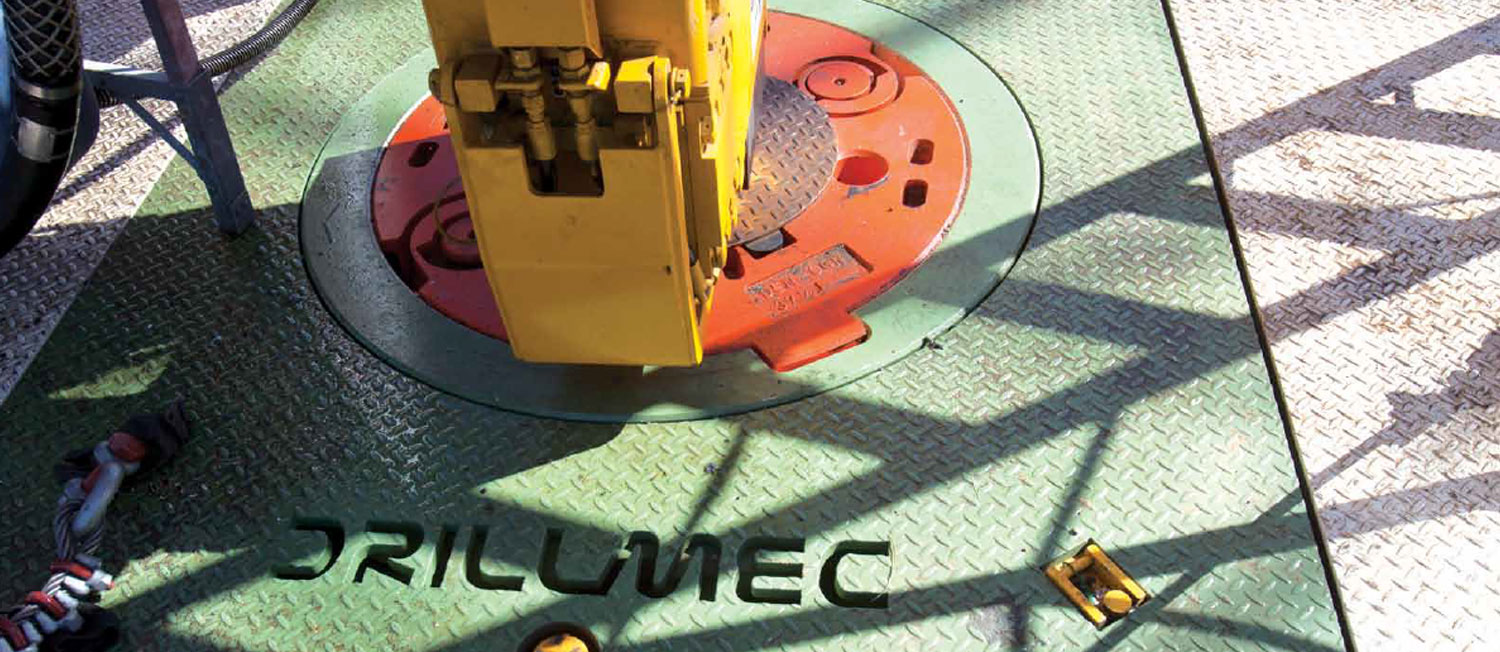

Rotary table

Drillmec rotary table is designed for rough conditions and complies with the strictest approvals for the drilling industry. Drillmec’s rotary table “R Type” are designed, in accordance with the industry standards, for drilling depths up to 30,000 FT and beyond. Driven by electric or hydraulic power, “R Type” are interchangeable with the most popular rotary table brands.

Drillmec’s quality department inspects all phases of manufacture and every item is tested in our premesis before delivery.

Categories: Drillmec, Equipment, Oil & Water, Rotary table

Related products

-

Land Rigs

<div class="first column"> <ul> <li>Drillmec’s deep roots in the manufacturing of drilling rigs start back in 1929 and since then continuously improved rig design by raising the pull-up capacity, enhancing safety, optimizing performance and minimizing environmental impact. Drillmec starting from Massarenti & Branham-design produces a full range of land rig packages to satisfy almost any need with successful achievements all over the world. Drillmec understands that drilling contractors objectives and conditions are constantly</li> <li>in flux and require different solutions to achieve results. Drillmec rigs are available in a wide range of specifications in order to fit custom configurations and capabilities</li> </ul> </div> <ul> <li><strong>Land Rigs - Swing Lift Series</strong> Drillmec produces swing lift rigs with raising lines or hydraulic cylinders. The Swing Lift Series is designed for fast and safe rig-up and rig-down, minimizing non-productive time.</li> <li><strong>DM SERIES </strong>( Swing Lift Series, Raising Lines)<strong> </strong> Swing Lift masts and substructures with hook load capacity from 340 to 907 metric tons (750,000 - 2,000,000 lbs).<strong>HSL SERIES </strong>(Hydraulic Swing Lift Series, Hydraulic Raising)<strong> </strong>Hydraulic Swing Lift masts and substructures with hook load capacity from 340 to 680 metric tons (750,000 - 1,500,000 lbs).</li> </ul>Read more -

Hydraulic Rigs Packages

<span style="font-size: 10pt;">Everything about the HH Series is designed for speed, safety and efficiency. You can tell just by looking it is not a conventional rig. From it self-erecting telescopic mast made from powerful hydraulic cylinders to the built-in integrated hydraulic top drive, HH rigs are designed to optimize your drilling plan from top to bottom. Automated systems, centralized control and few rig floor workers combine for a safer and more efficient drilling operation, better performance and reduced costs. Compared with rigs of equal power and capability, the HH Series creates a lower weight and smaller footprint reducing also environmental impact. The HH Series answers many demands of the E&P industry; increased productivity, fewer accidents and a reduced impact on the environment. By automating tasks on the floor and mobilizing components for efficiency, the HH Series’ unique design is the shape of things to come.</span> These are the main features: <ul> <li>Hands-off Automatic Handling of Tubulars (DP, Tubing, Casing) using built in: Top Drive – Pipe Handler - Jib Crane – Elevators</li> <li>Handling ESP Components with full access to the well center</li> <li>ESP cable guiding & clamping systems for tubing installation</li> <li>Rig automation to minimize manual involvement in the work</li> <li>Cyber control cabin with integrated control system</li> <li>Automated pipe handling including delivery of pipes between pipe rack and the completion rig</li> <li>Light and compact designs to allow simple and easy application on all different type of platforms</li> <li>Skidding and rotation system for full well path area covering</li> <li>Tailor made solutions for all different applications and operations<strong> </strong></li> </ul>Read more -

Top Drives

<div class="row productDescription"> <div class="col-sm-12"> <div id="descr-1" class="descr"> <div class="first column"> <strong>Hydraulic Top Drives</strong>Drillmec manufactures a full range of hydraulic top drives. Drillmec HTD series top drives can be fitted to almost any rig in order to increase the performance and help in operations such as directional or horizontal drilling. Drillmec designs top drive rails and torque tube starting from drawings of the customer rig or from data collected by </div> <div class="last column"> <p class="split">our technicians directly on the rig field. The torque tube provide the connection between the new HTD top drive and the existing rig. The HTD top drive is supplied with an independent hydraulic power pack and controls and with a transportation cradle designed to hold it and help in moving.</p> </div> <strong>Electric Top Drives</strong> </div> </div> </div> <div class="row productDescription"> <div class="col-sm-12"> <div id="descr-2" class="descr"> <div class="first column"> In the oil & gas industry top drive technology is used to increase performance and safety; from Drillmec solid experience in manufacturing hydraulic pipe handling and top drives, we introduce the ETD Series. The Drillmec Electric Top Drive is designed as transportable as well as permanent installed unit for deep drilling rigs with different mast types. The System is powered by an AC motor. The ETD Series is controlled by a separate control panel. <div class="first column"> The standard Top Drive version includes the following items: </div> <div class="last column"> <ul class="split"> <li class="split">Standard washpipe</li> <li>Link-tilt-system with position monitoring designed for high impacts</li> <li>Remote-controlled and manual IBOP</li> <li>Backup Clamp to make up and break the Top Drive drill pipe connection</li> <li>Guide rail system inducing the torque within the mast</li> <li>Electrical service loop</li> <li>Suitable for installation on any kind of mast and derrick</li> <li>Hanger assembly with integrated Counterbalance cylinders</li> </ul> </div> </div> </div> </div> </div>Read more -

SF 162 Marina Master Dredger

Italdraghe is specialised in the design and production of special purpose dredgers such as Marina Master, able to easily dredge under marinas’ pontoons.Read more

Reviews

There are no reviews yet.