| Max. Diameter | 3000 mm |

| Max. Depth | 80 m |

| Max. Torque | 210 kNm |

RT3-ST

RT3-ST model allows to drill holes of diameters from 600 to 2500 mm to various depths up to 80 m.

Some unique features of design and construction give the machine a high degree of efficiency and reliability:

– 185 HP, GM 4-53T diesel engine with ZF 4WG181 torque converter

– 3-roller table, with forced lubrication system and damping mounting through teflon rigs

– 16 ton pull down system through two 760 mm stroke hydraulic jacks

– fully detachable basic frame and subframe for ease of transport

– special steel Kelly bars with throughout welded extruded driving ribs

– intake air filter

Categories: Attachment Rigs, Piling & Foundation Machinery, Soilmec

Be the first to review “RT3-ST” Cancel reply

Related products

-

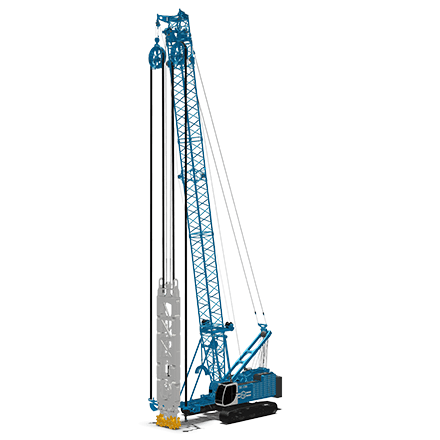

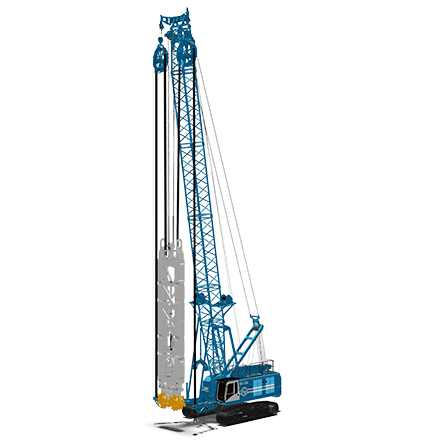

SC-120

The demand for diaphragm wall equipment suitable to urban areas and the stringent requirement of verticality make the hydromill Cougar a good and easy option to meet the customer’s needs. The Hose Wheels Design (HWD) is positioned below the cathead so that it can easily follow the hydromill movements with a tensioning and rewinding automatic system. It arises from the need to move simultaneously the hydraulic and bentonite mud circulation hoses to the cutting unit. The SC-120 Cougar is the high performance HWD series, which excavates more than 60 m of depth with approx. 900 HP ensuring a great level of production rates. The SC-120, complying with CE requests of EN16228 upon request, has been conceived to offer the best possible safety solutions. The equipment presents a new safe anti-falling system, handrails and ladders, lashing points, remote control boards and reduced speed mode in order to carry out the main assembly/disassembly operations and maintenance procedures in safe conditions. The DMS (Drilling Mate System), developed by Soilmec and installed on all the products of the range, allows the real-time monitoring of all the operating parameters and of the production process, including a dual-axis positioning sensor (triple-axis version as optional) that controls the geometry of the panel with 2D and 3D graphics print out.Read more -

SR-30

Soilmec rigs are self-mounting, easily transportable and designed to giving the best drilling solutions. The hydraulic drilling rig SR-30 has been specially designed for suiting the following applications: - LDP cased bore piles with casing driven directly by rotary head; - LDP deep uncased bored piles stabilized by drilling fluid or dry hole; - LHR (Low Head Room) – large diameter bored piles; - CFA (Continuous Flight Auger) piles by means of long auger string. The SR-30 is equipped with the DRILLING MATE SYSTEM (DMS) on 12' touch screen for monitoring and control of the rig performances and operating parameters.Read more -

SR-145

Soilmec rigs are self-mounting, easily transportable and designed to giving the best drilling solutions. The hydraulic drilling rig <strong>SR-145 </strong>has been specially designed for suiting the following applications: - <strong>LDP</strong> cased bore piles with casing driven directly by rotary head or optionally by casing oscillator powered by the base carrier itself; - <strong>LDP</strong> deep uncased bored piles stabilized by drilling fluid or dry hole; - <strong>CFA</strong> (Continuous Flight Auger) piles by means of long auger string; - <strong>CAP</strong> (Cased Augered Piles) piles with double independent rotary system; - <strong>DP</strong> (Displacement Piles) /<strong> TCT </strong>(traction compacting tool); - <strong>TJ</strong> (Turbojet®) / <strong>TTJ</strong> (Twin Shaft Turbojet) - soil consolidation; The <strong>SR-145 </strong>is equipped with the DRILLING MATE SYSTEM (DMS) on 12' touch screen for monitoring and control of the rig performances and operating parameters.Read more -

SC-100

The demand for diaphragm wall equipment suitable to urban areas and the stringent requirement of verticality make the hydromill Cougar a good and easy option to meet the customer’s needs. The Hose Wheels Design (HWD) is positioned below the cathead so that it can easily follow the hydromill movements with a tensioning and rewinding automatic system. It arises from the need to move simultaneously the hydraulic and bentonite mud circulation hoses to the cutting unit. The SC-100 Cougar is a compact hydromill equipment optimized for urban areas and low transportation weight (max 50 t; 110,000 lb). The DMS (Drilling Mate System), developed by Soilmec and installed on all the products of the range, allows the real-time monitoring of all the operating parameters and of the production process, including a dual-axis positioning sensor (triple-axis version as optional) that controls the geometry of the panel with 2D and 3D graphics print outRead more

Reviews

There are no reviews yet.