SF 362 multifunctional dredgers

Italdraghe specialises in the design and production of both standard and customised multifunctional dredgers.

Categories: Cutter Suction dredgers, Italdraghe, Oil & Water

Related products

-

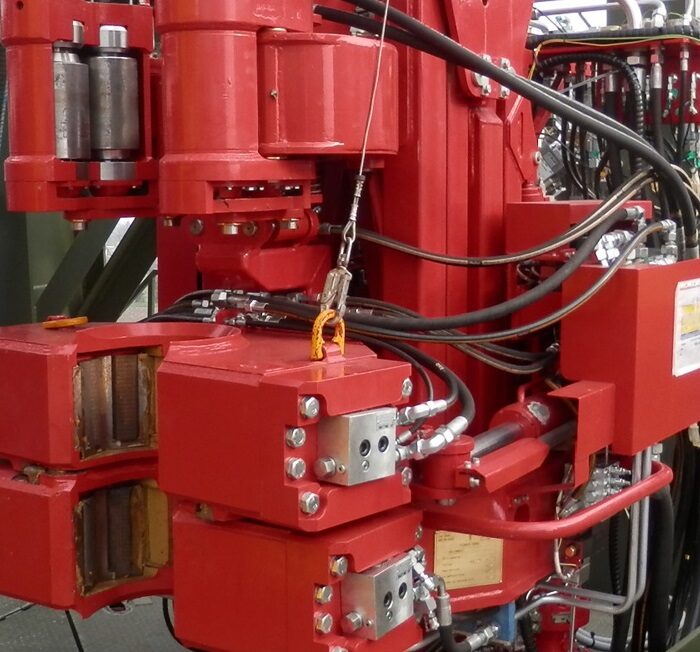

PCT – Compact Power Tong

<div class="row productDescription"> <div class="col-sm-12"> <div id="descr-1" class="descr"> <div class="first column"> <strong>DRILLMEC's Compact Power Tong</strong> is able to offer high torque performances with very quick operations. Drillmec PCT system, consist mainly of: </div> <div class="last column"> <ul class="split"> <li class="split">Set of hydraulic cylinders for vertical and horizontal power tong moving</li> <li>Spinning system</li> <li>Pedestral/Positioning</li> <li>Rotating clamps</li> </ul> </div> <strong>PCT Series Main features</strong> </div> </div> </div> <div class="row productDescription"> <div class="col-sm-12"> <div id="descr-2" class="descr"> <div class="first column"> <ul> <li>Can be installed directly on rig floor through a pedestal, can be powered by a Hydraulic Power Unit (stand alone system) or by the auxiliary rig’s HPU.</li> <li>Controls are located in the driller cabin and on the drill floor, connected to the PCT by cables, allowing remote operation handling at safe distance<strong> </strong></li> </ul> </div> <div class="last column"> <p class="split"><strong class="split">PCT Series Main Benefits:</strong></p> <ul> <li>Controls positioned on the handling arm frame available in case of emergency</li> <li>Easy installation and handling procedure, two pad eyes rated 17 ton each top mounted for lifting operations</li> <li>Equipped with one limit switch that stops upper clamp rotation during make-up phase</li> <li>High torque performance and wide OD range availability</li> </ul> </div> </div> </div> </div>Read more -

Mast & Derick

<div class="row productDescription"> <div class="col-sm-12"> <div id="descr-1" class="descr"> <div class="first column"> Drillmec manufactures derricks and masts for all applications, and, in addition, packages can be furnished with top drives, motion compensators, racking system, pipe handlers, elevators, top mounted flares and all derrick related equipment for complete packages. Drillmec offers a complete range of masts that can be telescopic, bootstrap, cantilever, and barge mounted units. In the design phase, particular care is given to weight, space, environmental loading conditions and operational capacities. </div> <div class="last column"> <p class="split">These are the main features of Drillmec derricks:</p> <ul> <li>Welded or bolted derricks</li> <li>Suitable for triple and quadruple stands accommodation</li> <li>Racking board equipped with racker and stand maker systems</li> </ul> </div> </div> </div> </div>Read more -

SGT 600 C cutter suction dredgers

1- Key features of Italdraghe dredgers :- – Up-to-date yet easy to operate – Easy to maintain – Centrally controlled by just one operator – Use of well-known branded components – Spacious, sound-proofed control cabin with 360° vision – Powerful, reliable pumps able to discharge over great distances – Spacious engine room with all round access to equipment – Cutter heads with replaceable teeth – Customised to specific client requirements – Dismountable for easy transportRead more -

Pipe Handling Equipment

Every rig operator is looking for greater efficiency and safer operations at the same time. Drillmec automated Pipe Handling Equipment accomplishes both in easy to operate and extremely reliable equipment. Power Catwalk & Pipe Shuttle Power Catwalk / Pipe Shuttle are the devices used for moving tubulars in complete safety from pipe racks to drill floor. Bridge Crane Racker Bridge Crane Racker is mounted on runway beams installed inside of the derrick, over the racking area. The lifting arm, equipped with a clamp, can be extended into the path of the traveling equipment and can handle various tubular sizes. The arm is equipped with a safety shear pin and safety cable to prevent damage should a collision occur. The racker can move the tubulars from racking board to well center, and viceversa. The bridge, 200 degree slewing and trolley functions are driven by rack and pinion drives and powered by rig hydraulic power. The control panels will be integrated into: derrick man cabin, driller’s control panel and driller’s assistant control panel. The Bridge Racker controls are configured such that the Racker can be run from a joystick controller on the derrick man control cabin or manually with the manually operated hydraulic controls in the derrick man control cabin, should there be any problems with the electrical controls. The system will be furnished with a complete zone management system to prevent collision between handler elements and travelling equipment. The Bridge Racker uses electrical components suitable for operation in Zone 2.Read more

Reviews

There are no reviews yet.