| Diesel Engine | 205 kW |

| Weight | 52 t |

| Max. Torque | 165 kNm |

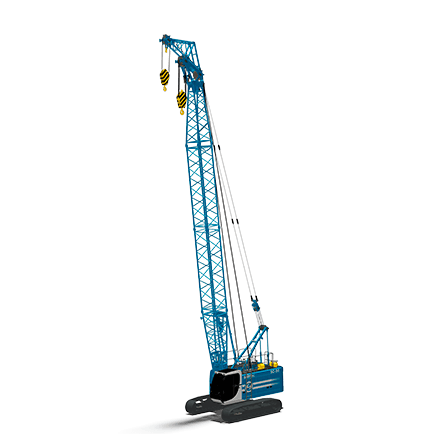

SF-65

The SF-65 drilling rig, is the evolution of the already existing equipment dedicated to Continuous Flight Auger drilling technique.

The upper structure of the SF-65 is mounted on Soilmec base carrier and has been designed to perform:

– CFA (Continuous Flight Auger) piles by means of long auger string.

The SF-65 is equipped with the DRILLING MATE SYSTEM (DMS) on 12′ touch screen for monitoring and control of the rig performances and operating parameters.

Reviews

There are no reviews yet.