SGT 200 cutter suction dredgers

1- Key features of Italdraghe dredgers :-

– Up-to-date yet easy to operate

– Easy to maintain

– Centrally controlled by just one operator

– Spacious, sound-proofed control cabin with 360° vision

– Powerful, reliable pumps able to discharge over great distances

– Spacious engine room with all round access to equipment

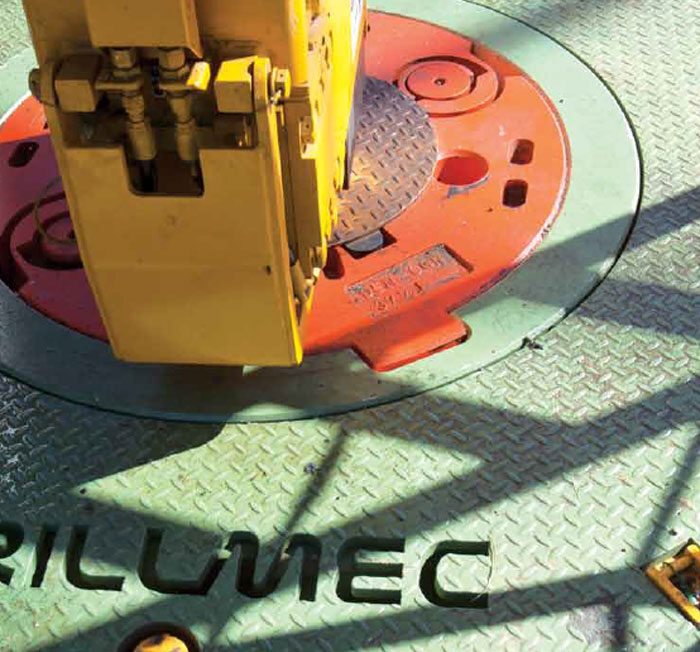

– Cutter heads with replaceable teeth

– Customised to specific client requirements

– Dismountable for easy transport – Use of well-known branded components

Reviews

There are no reviews yet.