| Panel Thickness | 700/1200 mm |

| Panel Width | 2600/3000 mm |

| Body Length | 10.5 m |

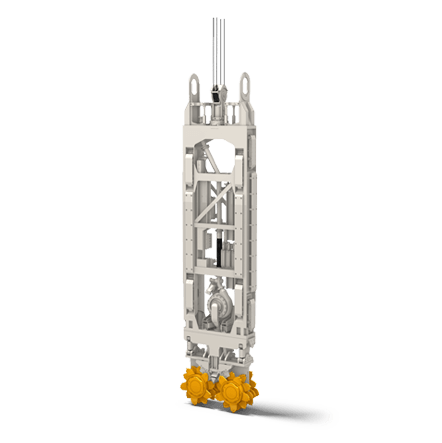

SH-30

The hydromill module is constituted by a heavy steel frame on which two milling drums and a centrifugal mud pump are mounted. In order to correct the module verticality deviation, 12 independent mobile flaps are positioned on the module surface. Furthermore, a simultaneous or independent tilting plate can be installed as optional for the best verticality correction, especially in case of leaned layers of rock. All Soilmec modules are set with a 2D or 3D sensor developed for the module positioning control, which is managed by the Hydromill DMS.

Soilmec has designed all its modules with a rotation system conceived for T-panel execution or for other module orientations. This specific feature gives the possibility to facilitate the job site operations, leading to a reduction in terms of cost and time.

The 30 t class module is especially designed for Cougar version and urban job sites. It can be fitted with a cutting unit up to 102 kNm torque in order to cover the major requests in terms of panel dimensions and soil stratigraphy. The module rotation system is included as a standard.

Reviews

There are no reviews yet.