| Diesel Engine | 164 kW |

| Weight | 29 t |

| Max. Torque | 130 kNm |

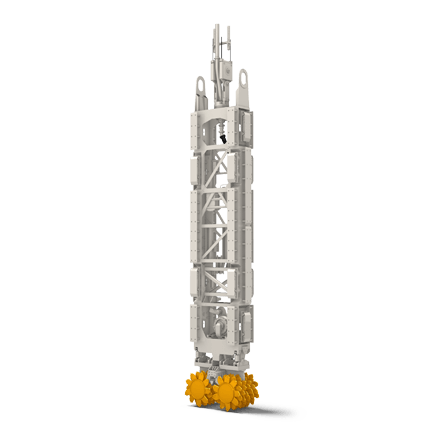

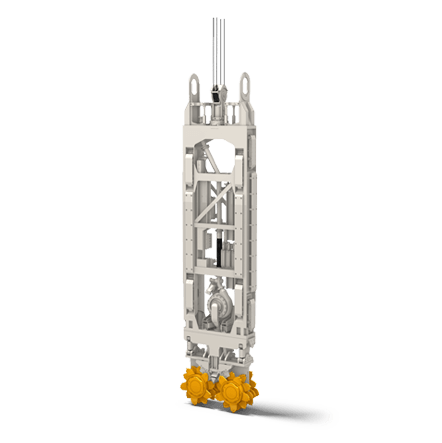

STM 30

STM-30 is a drill unit designed to be fast, highly productive and easy to operate. It’s a fully hydraulic drilling rig mounted on standard, heavy duty 6 x 4 truck. Thanks to its power, reliability and new configuration, the STM-30 meets with the needs for a high performance and easy to mobilize drilling rig.

The application is:

– LDP deep uncased bored piles stabilized by drilling fluid or dry hole.

Reviews

There are no reviews yet.