Great attention to details, reliability and technical solutions that go beyond any compromise, perfect operational capabilities all "packed" in one machine ! This leads to the top of its category because it can excite and satisfy at the same time the most demanding professional users in any working field : from agriculture and livestock, to small building and constructions, to earthmoving, landscaping and/or gardening, to municipality maintenance. With a low center of gravity, the articulated frame for an easy maneuvering granting a low turning radius, the self leveling with a double-cylinder system, two independent radiators for oil and water cooling, we have reached a great reliability of the machine, with a perfect fusion among top performances, safe maneuvering and driving comfort.

Read more

A new machine, a new structural configuration for a new way of working: a unique and innovative concept that combines the advantages of the rigid frame with the articulated chassis in a winning combination: T45. Supplied with four-wheel steering and oscillating rear axle it allows tight turning radius but very high levels of stability and security. The hydrostatic servo-assisted steering system, the articulated frame together with four steering wheels, each powered by an indipendent wheel motor, allows the operator, despite the size and the weight of the machine, to maintain the keep the driving of the machine always under control in a simple and safe way, thanks to the absolute directional stability of the vehicle.

Read more

<ul>

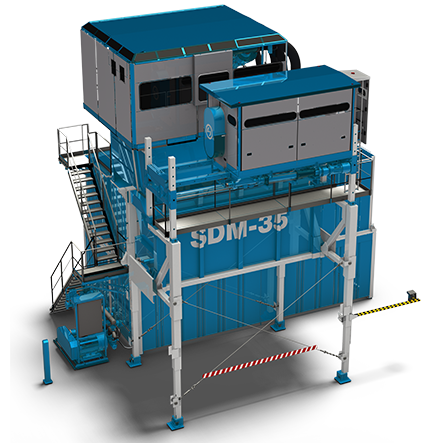

<li>STOUT CONSTRUCTION</li>

<li>EASY INSTALLATION</li>

<li>HIGH RELIABILITY</li>

<li>4 MODELS</li>

<li>MANUAL / AUTOMATIC</li>

</ul>

Read more

<strong>Soilmec </strong>offer a machine, a technology and a solution to meet foundation needs. A comprehensive and technologically advanced jobsite, enriched by IPC technology with highly performing auxiliary equipment and accessories in a <em>Mud product line</em> dedicated to the use of bentonite and slurry.

<ul>

<li>Mud treatment unit</li>

<li>Centrifugal self-priming pumps</li>

<li>Mixers</li>

<li>Desanders</li>

</ul>

Read more

<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-1" class="descr">

<div class="first column">

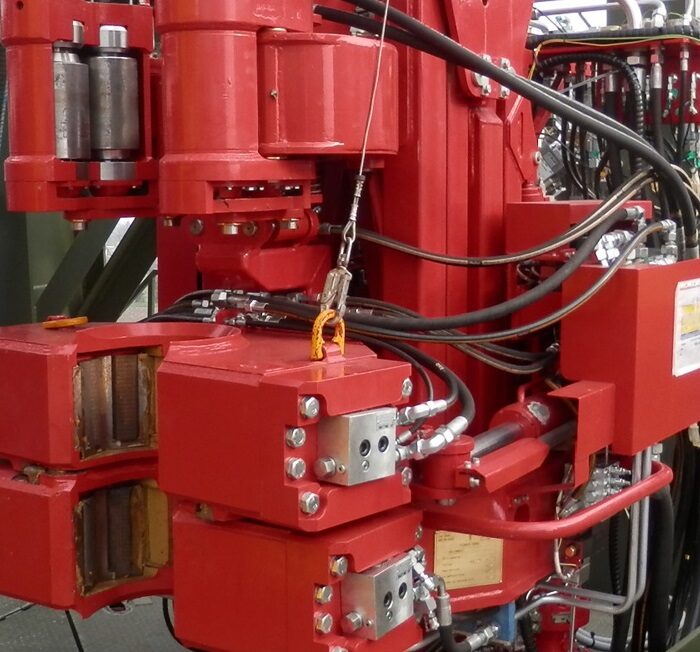

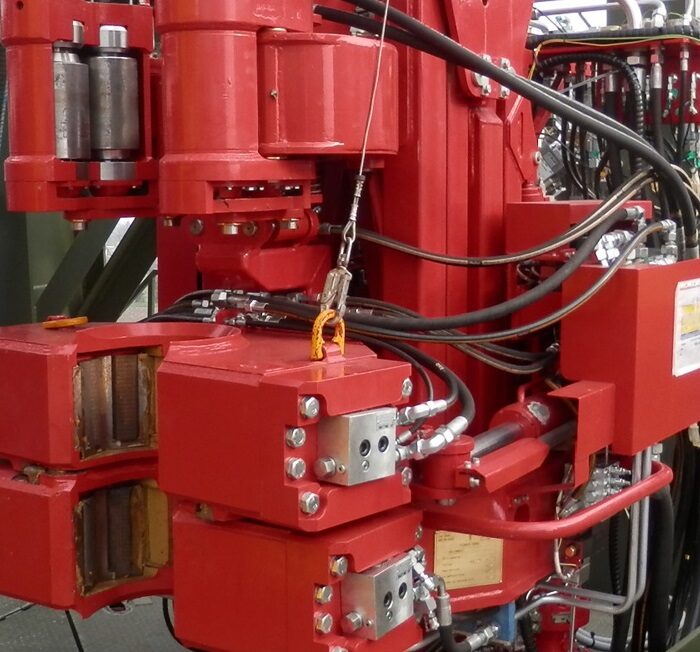

<strong>DRILLMEC's Compact Power Tong</strong> is able to offer high torque performances with very quick operations.

Drillmec PCT system, consist mainly of:

</div>

<div class="last column">

<ul class="split">

<li class="split">Set of hydraulic cylinders for vertical and horizontal power tong moving</li>

<li>Spinning system</li>

<li>Pedestral/Positioning</li>

<li>Rotating clamps</li>

</ul>

</div>

<strong>PCT Series Main features</strong>

</div>

</div>

</div>

<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-2" class="descr">

<div class="first column">

<ul>

<li>Can be installed directly on rig floor through a pedestal, can be powered by a Hydraulic Power Unit (stand alone system) or by the auxiliary rig’s HPU.</li>

<li>Controls are located in the driller cabin and on the drill floor, connected to the PCT by cables, allowing remote operation handling at safe distance<strong> </strong></li>

</ul>

</div>

<div class="last column">

<p class="split"><strong class="split">PCT Series Main Benefits:</strong></p>

<ul>

<li>Controls positioned on the handling arm frame available in case of emergency</li>

<li>Easy installation and handling procedure, two pad eyes rated 17 ton each top mounted for lifting operations</li>

<li>Equipped with one limit switch that stops upper clamp rotation during make-up phase</li>

<li>High torque performance and wide OD range availability</li>

</ul>

</div>

</div>

</div>

</div>

Read more

Every rig operator is looking for greater efficiency and safer operations at the same time. Drillmec automated Pipe Handling Equipment accomplishes both in easy to operate and extremely reliable equipment.

Power Catwalk & Pipe Shuttle

Power Catwalk / Pipe Shuttle are the devices used for moving tubulars in complete safety from pipe racks to drill floor.

Bridge Crane Racker

Bridge Crane Racker is mounted on runway beams installed inside of the derrick, over the racking area. The lifting arm, equipped with a clamp, can be extended into the path of the traveling equipment and can handle various tubular sizes. The arm is equipped with a safety shear pin and safety cable to prevent damage should a collision occur. The racker can move the tubulars from racking board to well center, and viceversa.

The bridge, 200 degree slewing and trolley functions are driven by rack and pinion drives and powered by rig hydraulic power.

The control panels will be integrated into: derrick man cabin, driller’s control panel and driller’s assistant control panel.

The Bridge Racker controls are configured such that the Racker can be run from a joystick controller on the derrick man control cabin or manually with the manually operated hydraulic controls in the derrick man control cabin, should there be any problems with the electrical controls.

The system will be furnished with a complete zone management system to prevent collision between handler elements and travelling equipment.

The Bridge Racker uses electrical components suitable for operation in Zone 2.

Read more

<div class="fl-module fl-module-rich-text fl-node-584ad463c03e7" data-node="584ad463c03e7">

<div class="fl-module-content fl-node-content">

<div class="fl-rich-text">

<h2><span style="font-size: 12pt;"><strong>PLA168, compact in size suitable for a city use</strong></span></h2>

Telescopic configuration with a fixed section and two telescopic sliding booms. This machine is particularly compact in size with vertical stabilization in shape, suitable for urban use. A robust design suitable for heavy use such as pruning, maintenance and costruction, electrical maintenance and road signs/advertising. Simple and fast, is the most compact in its category. Electro-hydraulic model with internal pipes.

</div>

</div>

</div>

Read more

<div class="fl-module fl-module-rich-text fl-node-584ad940af30e" data-node="584ad940af30e">

<div class="fl-module-content fl-node-content">

<div class="fl-rich-text">

<h2><span style="font-size: 12pt;"><strong>PLA190, the performance optimization</strong></span></h2>

Double stabilization area to optimize the performance both in confined spaces and in more accessible areas. Vertical stabilization system allows this unit to work with outriggers deployed within the truck body. Simple and fast in stabilization and use, with precise electro-hydraulic controls on basket. Electro-hydraulic model with internal pipes.

</div>

</div>

</div>

Read more