Soilmec rigs are self-mounting, easily transportable and designed to giving the best drilling solutions.

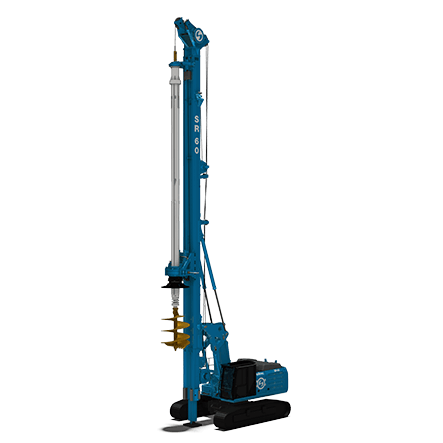

The hydraulic drilling rig <strong>SR-60 </strong>has been specially designed for suiting the following applications:

- <strong>LDP</strong> cased bore piles with casing driven directly by rotary head or optionally by casing oscillator powered by the base carrier itself;

- <strong>LDP</strong> deep uncased bored piles stabilized by drilling fluid or dry hole;

- <strong>CFA</strong> (Continuous Flight Auger) piles by means of long auger string;

Read more

Soilmec rigs are self-mounting, easily transportable and designed to giving the best drilling solutions.

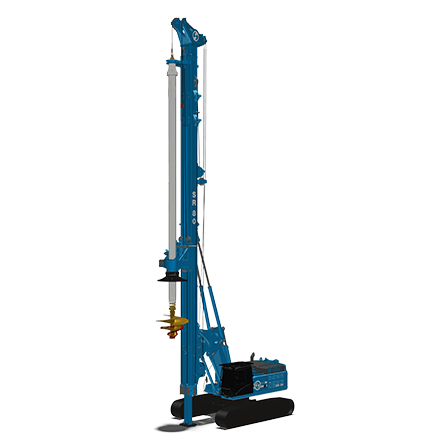

The hydraulic drilling rig <strong>SR-60 </strong>has been specially designed for suiting the following applications:

- <strong>LDP</strong> cased bore piles with casing driven directly by rotary head or optionally by casing oscillator powered by the base carrier itself;

- <strong>LDP</strong> deep uncased bored piles stabilized by drilling fluid or dry hole;

- <strong>CFA</strong> (Continuous Flight Auger) piles by means of long auger string;

Read more

Soilmec rigs are self-mounting, easily transportable and designed to giving the best drilling solutions.

The hydraulic drilling rig <strong>SR-65</strong> has been specially designed for suiting the following applications:

- <strong>LDP</strong> cased bore piles with casing driven directly by rotary head or optionally by casing oscillator powered by the base carrier itself;

- <strong>LDP</strong> deep uncased bored piles stabilized by drilling fluid or dry hole;

- <strong>CFA</strong> (Continuous Flight Auger) piles by means of long auger string;

The SR-65 is equipped with the DRILLING MATE SYSTEM (DMS) on 12' touch screen for monitoring and control of the rig performances and operating parameters.

Read more

Soilmec rigs are self-mounting, easily transportable and designed to giving the best drilling solutions.

The hydraulic drilling rig <strong>SR-65</strong> has been specially designed for suiting the following applications:

- <strong>LDP</strong> cased bore piles with casing driven directly by rotary head or optionally by casing oscillator powered by the base carrier itself;

- <strong>LDP</strong> deep uncased bored piles stabilized by drilling fluid or dry hole;

- <strong>CFA</strong> (Continuous Flight Auger) piles by means of long auger string;

The SR-65 is equipped with the DRILLING MATE SYSTEM (DMS) on 12' touch screen for monitoring and control of the rig performances and operating parameters.

Read more

Soilmec rigs are self-mounting, easily transportable and designed to giving the best drilling solutions.

The hydraulic drilling rig <strong>SR-75 </strong>has been specially designed for suiting the following applications:

- <strong>LDP</strong> cased bore piles with casing driven directly by rotary head or optionally by casing oscillator powered by the base carrier itself;

- <strong>LDP</strong> deep uncased bored piles stabilized by drilling fluid or dry hole;

- <strong>LHR</strong> (Low Head Room) – large diameter bored piles;

- <strong>CFA</strong> (Continuous Flight Auger) piles by means of long auger string;

- <strong>CAP</strong> (Cased Augered Piles) piles with double independent rotary system;

- <strong>DP</strong> (Displacement Piles) / <strong>TCT</strong> (traction compacting tool);

- <strong>TJ</strong> (Turbojet®) / <strong>TTJ</strong> (Twin Shaft Turbojet) - soil consolidation;

- <strong>RCDS</strong> (Reverse Circulation Drilling System) on demand.

The <strong>SR-75</strong> is equipped with the DRILLING MATE SYSTEM (DMS) on 12' touch screen for monitoring and control of the rig performances and operating parameters.

Read more

Soilmec rigs are self-mounting, easily transportable and designed to giving the best drilling solutions.

The hydraulic drilling rig <strong>SR-75 </strong>has been specially designed for suiting the following applications:

- <strong>LDP</strong> cased bore piles with casing driven directly by rotary head or optionally by casing oscillator powered by the base carrier itself;

- <strong>LDP</strong> deep uncased bored piles stabilized by drilling fluid or dry hole;

- <strong>LHR</strong> (Low Head Room) – large diameter bored piles;

- <strong>CFA</strong> (Continuous Flight Auger) piles by means of long auger string;

- <strong>CAP</strong> (Cased Augered Piles) piles with double independent rotary system;

- <strong>DP</strong> (Displacement Piles) / <strong>TCT</strong> (traction compacting tool);

- <strong>TJ</strong> (Turbojet®) / <strong>TTJ</strong> (Twin Shaft Turbojet) - soil consolidation;

- <strong>RCDS</strong> (Reverse Circulation Drilling System) on demand.

The <strong>SR-75</strong> is equipped with the DRILLING MATE SYSTEM (DMS) on 12' touch screen for monitoring and control of the rig performances and operating parameters.

Read more

Soilmec rigs are self-mounting, easily transportable and designed to giving the best drilling solutions.

The hydraulic drilling rig <strong>SR-80</strong> has been specially designed for suiting the following applications:

-<strong> LDP</strong> cased bore piles with casing driven directly by rotary head or optionally by casing oscillator powered by the base carrier itself;

-<strong> LDP</strong> deep uncased bored piles stabilized by drilling fluid or dry hole;

- <strong>CFA</strong> (Continuous Flight Auger) piles by means of long auger string;

Read more

Soilmec rigs are self-mounting, easily transportable and designed to giving the best drilling solutions.

The hydraulic drilling rig <strong>SR-80</strong> has been specially designed for suiting the following applications:

-<strong> LDP</strong> cased bore piles with casing driven directly by rotary head or optionally by casing oscillator powered by the base carrier itself;

-<strong> LDP</strong> deep uncased bored piles stabilized by drilling fluid or dry hole;

- <strong>CFA</strong> (Continuous Flight Auger) piles by means of long auger string;

Read more

Soilmec rigs are self-mounting, easily transportable and designed to giving the best drilling solutions.

The hydraulic drilling rig <strong>SR-95 </strong>has been specially designed for suiting the following applications:

- <strong>LDP</strong> cased bore piles with casing driven directly by rotary head or optionally by casing oscillator powered by the base carrier itself;

- <strong>LDP</strong> deep uncased bored piles stabilized by drilling fluid or dry hole;

- <strong>CFA</strong> (Continuous Flight Auger) piles by means of long auger string;

- <strong>CAP</strong> (Cased Augered Piles) piles with double independent rotary system;

- <strong>DP</strong> (Displacement Piles) /<strong> TCT </strong>(traction compacting tool);

- <strong>TJ</strong> (Turbojet®) / <strong>TTJ</strong> (Twin Shaft Turbojet) - soil consolidation;

- <strong>RCDS</strong> (Reverse Circulation Drilling System) on demand.

The <strong>SR-95 </strong>is equipped with the DRILLING MATE SYSTEM (DMS) on 12' touch screen for monitoring and control of the rig performances and operating parameters.

Read more

The <strong>ST-20</strong> tunnelling rig is ideal for sub-horizontal consolidation in tunnels with a work radius of between 1512 mm and 4696 mm (with the drilling mast horizontal at 0°). The useful stroke of the rotary allows treatments of up to 14 m (16 with the optional extension).

The drilling mast can be folded in at both ends, reducing the overall dimensions, to make the rig easier to transport both underground and on the road at the end of the job.

The machine has two motors (diesel and electric) of a suitable size for each single motor to perform all the drilling, traversing and positioning operations of the crawler.

The following <strong>drilling techniques</strong> can be applied using the ST-20:

- Rotation (with or without casing)

- Rotopercussion by means of Top Hammer (with or without casing)

- Rotopercussion by means of Down the Hole Hammer (with Tubex, Odex or Simmetrix superjews system)

Read more

<strong>ST-60</strong> tunnelling rig project was developed to meet the growing need for sub-horizontal consolidation in large-section tunnels using single-boom equipment working with the full section method as an excellent alternative to the double-boom type system traditionally used for this type of job.

The equipment is very flexible and fast to use, also in relation to the importance of the treatments to perform. To reach the maximum heading stroke points with respect to ground level, a special system of thrust blocks and sliding blocks was designed to reach these points in total safety. The machine has a mast for 19000 mm treatments in one pass and 24000 m treatments with matching chuck and optional extensions.

The maximum extension height at 0° with respect to ground level is 10700 mm.

The variability of the height of the thrust block axis of rotation from 850 mm to 4250 mm combined with the column extension allows a work radius of from 3700 mm to 6500 mm. Tunnel lining is over 180°.

Fitted with two motors (diesel and electric) for both drilling and traversing, guaranteeing performance also in case of a breakdown of one of the two units.

<strong>The following drilling techniques can be applied using the ST-60:</strong>

- Rotation (with or without casing)

- Rotopercussion by means of Top Hammer (with or without casing)

- Rotopercussion by means of Down the Hole Hammer (with Tubex, Odex or Simmetrix superjews system)

Read more