<div class="first column">

In addition to Pre-FEED, FEED and EPC of drilling packages and drilling modules, DRILLMEC offers a comprehensive line of Tender Assisted DES to be applied not only on fixed platforms and jackets, but also for deeper water operations on TLPs and SPARs. DRILLMEC DES design focuses on the following key advantages and main aspects:

<ul>

<li>Light weight design</li>

<li>Minimized quantity of loads - downt to 3, depending on client's preferences and lifting requirements</li>

<li>Quick and safe rig-up operations</li>

<li>Maximized tripping speed and set-up for offline operations</li>

</ul>

</div>

<div class="last column">

<p class="split">Drilllmec's typical activities for Tender Assisted DES and Modular Rigs include the following:</p>

<ul>

<li>Conceptual design, front-end engineering and detailed engineering</li>

<li>Project Management</li>

<li>Supply of complete drilling equipment, mud equipment and third party equipment</li>

<li>Fabrication and/or construction supervision</li>

<li>Installation, testing, commissioning and site assistance</li>

<li>24/7 After sales assistance and support</li>

</ul>

</div>

Read more

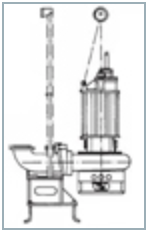

<ul>

<li>EASY ASSEMBLY</li>

<li>REDUCED MAINTENANCE</li>

<li>HIGH RELIABILITY</li>

<li>6 MODEL</li>

<li>3 SHAPES</li>

</ul>

Read more

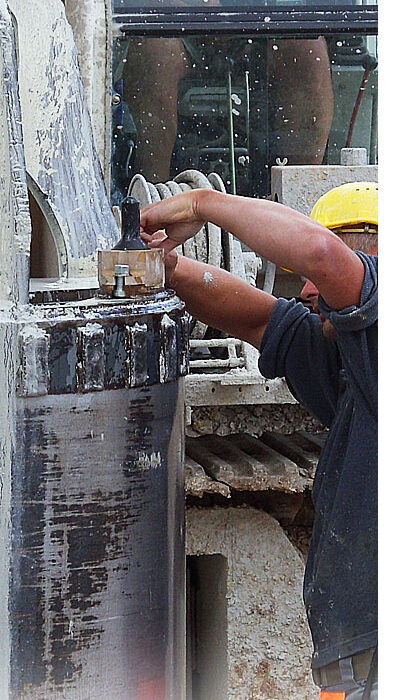

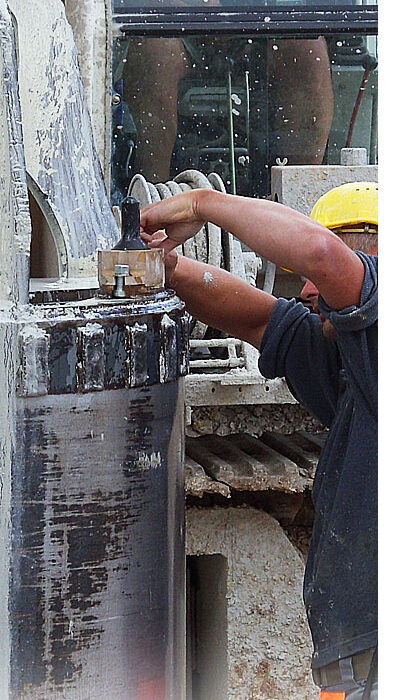

<p align="justify"><span style="font-size: 8pt;">nspired by the technology used by oil rig directional drilling, the TIGOR is an instrumented drilling rod comprising deviation measurement sensors, onboard electronics and batteries. The assembly, available in 2 versions, the single fluid and the double fluid, consists of a 1 metre long non-magnetic rod.</span></p>

<p align="justify"><span style="font-size: 8pt;"><b>TIGOR single fluid: </b>Available in diameters 89 and 114, the TIGOR has a central tube that carries the drilling fluid or the high pressure slurry.</span></p>

<span style="font-size: 8pt;"><b>TIGOR double fluid :</b> Available in diameters 127 and 139, the TIGOR double fluid has a central tube that carries the drilling fluid or the high pressure slurry and also a lateral pipe conveying air.</span>

<span style="font-size: 8pt;">Regardless of version, the TIGOR always includes sensors for measuring the inclinations in two perpendicular planes and the azimuth in relation to the magnetic North.</span>

Read more

<span style="font-size: 8pt;">The DIALOG is an instrument designed to measure and control specialist foundation processes. Equipped with a touch screen that is both rugged and ergonomic, it is easy to use.

</span><span style="font-size: 8pt;">The DIALOG can be used for efficient data synchronisation between users permanently or intermittently connected to a corporate network.

</span><span style="font-size: 8pt;">Configuration and updating as well as schedule settings can be carried out remotely. The DIALOG is equipped with an internal GPS for localisation purposes; it can also be configured for monitoring machine components.</span>

Read more

<div class="titolo">

<h1>Drilling Mate System</h1>

<div class="serie"></div>

</div>

<div class="row">

<div class="col-md-6">

DMS - <strong>Drilling Mate System</strong> - is a project born in the mid-90s with the aim of providing to both operator and jobsite personnel, an active instrument to control and interact with the machine (sensors, safety devices, diesel engine, drilling parameters, etc.).

Soilmec, having perceived an upcoming electronic revolution in the field of drilling machines, used the extensive experience acquired on jobsites to develop a tool that would allow the operator to manage both machine and production.

</div>

</div>

Read more

<div class="row productDescription">

<div class="col-sm-12">

<div id="descr-1" class="descr">

<div class="first column">

<strong>DRILLMEC’s GDS Series</strong> is the new generation of Compact Gear Driven Single Speed Drawworks built to improve safety and performance. The compact design makes this product line the state of art to the oil industry for onshore application and excellent for offshore application in case of new installation, refurbishment and upgrading of existing ones.Complete with a modern Automatic Drilling System, PLC based product, AC Motors frequency drive is capable of holding full load at zero speed indefinitely and high safety emergency disc brake system with negative calipers. The package is designed to reduce noise, vibration and maintenance at highest performance level. The GDS Series replaces the MAS Series and it is fully compatible with any rig designs.

<strong>Drillmec GDM Series</strong> Gear Driven Drawworks are the result of years of experience with the main objective of continuous improvement over decades

</div>

<div class="last column">

<p class="split">of innovation. GDM drawworks consists of the following main components: drum, motors, reduction gear, brake and auxiliary brake. Drillmec produces a wide range of drawworks engineered for today’s tough drilling challenges. Like with other Drillmec drilling equipment, our Gear Driven Drawworks can be fitted to all land rigs with power ranging from 1500 to 3000 hp with a nominal depth range from 3500 to 10000 meters (11000 ft to 32000 ft).</p>

<strong>DRILLMEC’s GDS & GDM Series Drawworks for Offshore Application</strong> are developed to offer superior performance for a variety of drilling operations and work environments for both shallow and deep water drilling applications. The GD Series for Offshore Application are characterized by a compact footprint & size, durability, effectiveness, and energy-efficiency even in deep water applications.

</div>

</div>

</div>

</div>

Read more

Key features of excavator dredging head :-

– Simple quick-fit installation

– Low maintenance costs

– Easy to use one-man operation

– Easy to transport – Compatible with all brands of hydraulic excavator

– Driven directly by excavator’s own power source

– Ideal for hard-to-access stretches of water

– Suitable for working from both on-land and floating excavators

Read more

Betek, Kennametal (Road Construction, Diaphragm wall cutter teeth & Trenching Tools), China Teeth, Roller Bits & Tricon Bits .

Read more