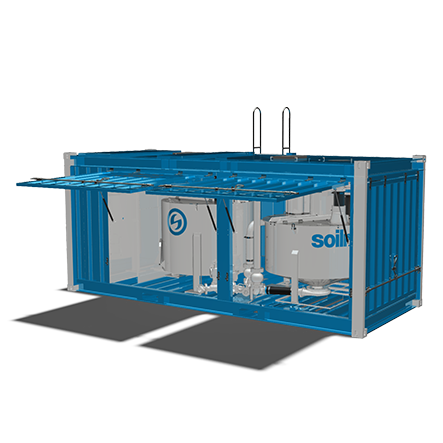

<strong>Soimec </strong>offer a machine, a technology and a solution to meet foundation needs. A comprehensive and technologically advanced jobsite, enriched by IPC technology with highly performing auxiliary equipment and accessories in a <em>Grout product line</em> dedicated to the preparation and injection of water/cement mix.

<ul>

<li>Agitators</li>

<li>Turbomixers</li>

<li>Injectors</li>

<li>Packer Grout</li>

<li>Mixing Plant</li>

<li>Mixing Units</li>

<li>High Pressure Pumps</li>

</ul>

Read more

A Wide Range of Reliable , Heavy - Duty Thrusters Designed to Guarantee Continuous Operation in All Conditions.

Read more

A Wide Range of Reliable , Heavy - Duty Thrusters Designed to Guarantee Continuous Operation in All Conditions.

Read more

A Wide Range of Reliable , Heavy - Duty Thrusters Designed to Guarantee Continuous Operation in All Conditions.

Read more

1- Key features of Italdraghe MA harvesters :-

– Designed to match specific customer requirements

– Can be disassembled for transport

– Self-propelled

– Self-unloading

– Easy to operate - Limited operating costs

Read more

<ul>

<li>STOUT CONSTRUCTION</li>

<li>REDUCED MAINTENANCE</li>

<li>HIGH RELIABILITY</li>

<li>6 SIZES</li>

<li>18 MODELS</li>

</ul>

Read more

<div class="first column">

<span style="font-size: 10pt;">Everything about the HH Series is designed for speed, safety and efficiency. You can tell just by looking it is not a conventional rig. </span>

<span style="font-size: 8pt;"><span style="font-size: 10pt;">From it selferecting telescopic mast made from a single powerful hydraulic cylinder to the built-in integrated hydraulic top drive, HH rigs are designed to optimize your drilling plan from top to bottom. Automated systems, centralized control and few rig floor workers combine for a safer and more efficient drilling operation, better performance and reduced costs. The HH Series drilling processes are largely automated and centrally operated from the climate controlled driller’s cabin. Stuck pipe becomes less of an issue with features that allow automatic drilling even with preset WOBs and ROPs or top drive back reaming.</span>

</span>

</div>

<div class="last column"></div>

Read more

<div class="details">

By gaining a comprehensive understanding to achieve the evolving, ambitious goals of modern construction business, we have tested and developed our hammers to provide the best possible performance under all conditions. Our versatile selection of equipment ensures that for every construction challenge, the ideal solution can be found.

</div>

Read more

<span style="font-size: 10pt;">Everything about the HH Series is designed for speed, safety and efficiency. You can tell just by looking it is not a conventional rig. From it self-erecting telescopic mast made from powerful hydraulic cylinders to the built-in integrated hydraulic top drive, HH rigs are designed to optimize your drilling plan from top to bottom. Automated systems, centralized control and few rig floor workers combine for a safer and more efficient drilling operation, better performance and reduced costs. Compared with rigs of equal power and capability, the HH Series creates a lower weight and smaller footprint reducing also environmental impact. The HH Series answers many demands of the E&P industry; increased productivity, fewer accidents and a reduced impact on the environment. By automating tasks on the floor and mobilizing components for efficiency, the HH Series’ unique design is the shape of things to come.</span>

These are the main features:

<ul>

<li>Hands-off Automatic Handling of Tubulars (DP, Tubing, Casing) using built in: Top Drive – Pipe Handler - Jib Crane – Elevators</li>

<li>Handling ESP Components with full access to the well center</li>

<li>ESP cable guiding & clamping systems for tubing installation</li>

<li>Rig automation to minimize manual involvement in the work</li>

<li>Cyber control cabin with integrated control system</li>

<li>Automated pipe handling including delivery of pipes between pipe rack and the completion rig</li>

<li>Light and compact designs to allow simple and easy application on all different type of platforms</li>

<li>Skidding and rotation system for full well path area covering</li>

<li>Tailor made solutions for all different applications and operations<strong> </strong></li>

</ul>

Read more

<ul>

<li>COMPACT CONSTRUCTION</li>

<li>PLANETARY GEAR</li>

<li>F.E.M. / ISO 15020 STANDARD</li>

<li>SMOOTH/GROOVED DRUM</li>

<li>NEGATIVE BRAKE</li>

<li>FREE WHEEL</li>

<li>SPECIAL MODELS</li>

</ul>

Read more

Junttan’s new vertical travel lead Leader packages can be integrated to any brand crawler crane. The new Junttan LP25 and LP32 leader package kit consists of a vertical travel lead, hydraulic spotter system, cathead, Junttan controls, and a Junttan hydraulic hammer. The maximum pile length with the Junttan LP25 with a Junttan 9-ton hammer is maximum 25 m (82 ft) and with the Junttan LP32 it is 32 m (105 ft). The bigger LP32 package is designed to be used with up to a 14-ton Junttan hydraulic hammer.

Depending on the crawler crane, the Junttan hydraulic hammer can be powered either with the crane’s own hydraulics or with a Junttan Power pack. If needed, the power pack can be mounted on a support frame in the rear of the crawler crane.

The Junttan Leader package offers optimal reach and driving also for battered piles. It enables a 15-degree forward inclination and a 15-degree backward inclination as well as a 9-degree lateral inclination. The Junttan long-reach leader design enables piling to be carried out as far as 10 m (30 ft) away from the crane’s crawlers. Operating is easy with the Junttan controls for the leader and the hydraulic hammer.

Read more